- Home » News » World News

Robot firm raises $30m to automate ‘impossible’ tasks

A German robot control specialist has raised $30m of funding for its AI systems that, it claims, can automate manufacturing processes that could not be automated previously. Berlin-based Micropsi Industries, founded in 2014, says that its Mirai technology already does what others can only promise.

The technology allows human operators to train robots to perform hand-eye-coordinated action using cameras and sensors that react in real-time to dynamic conditions in industrial environments. Once configured, a robot arm can perceive its workspace and adjust its movements as it performs a task.

Currently, the technology works with robots from ABB and Universal Robots. Part of the new funding will be used to extend its use to robots from other manufacturers.

The technology is already being used in assembly, material-handling and quality control applications in a range of industries. Customers include Siemens Energy, and Europe’s largest manufacturer of domestic appliance, BSH.

For most existing industrial robot applications, specialists need to develop software code line-by-line to trigger the individual movements of the arms. This is complex, expensive and makes robots inflexible, because variations in positions or materials can throw the robots off.

Micropsi says that Mirai changes this. Workers train robots through demonstration, using AI (artificial intelligence). They guide the robot arm through a task, which it learns and then carries out the movements autonomously. The robot can handle changes in the environment, keeping it flexible, even if conditions change. The training process takes a few hours and can be done by operators with no robot programming skills.

“Our technology makes it easy to transfer dynamic motion know-how from humans to robots,” explains Micropsi’s CEO and co-founder, Ronnie Vuine. “We have not optimised the textbook approach for specific applications, but took a radically different approach inspired by how humans coordinate motions. Mirai is a proven and independent technology that’s working 24/7 in the factories of our customers. That is what convinced our investors: here is a company that can already verifiably do what many current start-ups only promise to develop.”

As well as expanding Mirai to more robot platforms, the new funding will be used to expand Micropsi’s operations in the US, and to ramp up sales. The company is also looking to expand into new application areas such as laboratory automation and logistics.

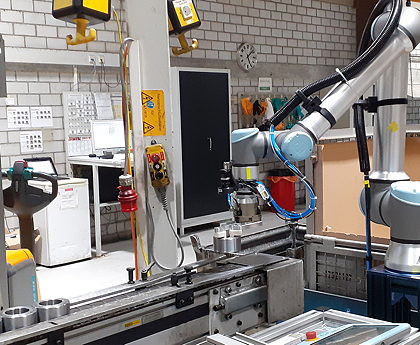

In one existing application, Mirai has been used to automate machine-tending for a high-volume milling station operated by the gear manufacturer ZF. A Universal Robots cobot picks up metal rings from a crate and places them on a conveyor belt ready for manufacturing steps that turn the rings into gears.

Initially, ZF performed the ring-picking task using a conventionally programmed robot but encountered problems because the rings are packed in layers, their positions can vary by up to 30mm in any direction, their surfaces can be covered by oil and ruse, and bubble wrap in the crates can obscure parts of the rings.

Adopting the Mirai approach has speeded up the operation and made it more reliable. The robot’s own controller moves the arm above the crate, where the Mirai system takes over, moving the robot to the closest ring and using a Schunk gripper to grab the ring. The robot’s controller then resumes control, picking up the ring and moving it to the conveyor belt. Training the Mirai system took just four days.

Micropsi: Twitter LinkedIn Facebook