- Home » News » World News

Swiss start-up uses robot microfactories to create large parts

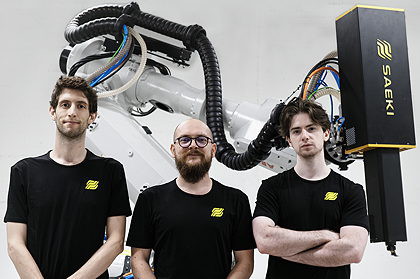

A Swiss company has emerged from a period of stealth development to offer a new service for creating large components using technologies such as robots, 3D printing and machine vision. Lupfig-based Saeki, which was founded in 2021, has attracted $2.3m of seed funding to build automated plants that will produce large-scale components for industries such as automotive, construction, aerospace, marine and energy.

Currently, to develop items such as lightweight carbon fibre elements, or to build concrete floor slabs, buyers may have to wait months and spend vast sums of money to receive a first sample and only then build a prototype – let alone consider reiterating for any flaws.

Saeki’s robots-as-a-service model aims to remove this bottleneck, allowing buyers to innovate rapidly, and expand their services and offerings in ways they have not been able to do before. For large-scale items, it adds, this has previously been impossible.

For example, the company has developed a new method for producing custom concrete formwork cost-effectively, allowing the building industry to turn complex designs into reality, without costly, time-consuming manual production of formwork, while also saving concrete and cutting CO2 emissions.

“There is a need for large, one-off (custom) components, that are mostly used once a couple of times at most, then scrapped,” explains Saeki co-founder and CEO, Andrea Perissinotto. “Manufacturing these parts, from the moulds to make concrete elements to the tooling required to build composite rockets, is labour-intensive, has long lead times, and is very expensive. Moreover, these factors delay hardware iteration to get to the final product.

“For vast swathes of industry it’s not practical to own and manage robots that can create what you need quickly,” he adds. “We are at the forefront of addressing this and democratising access to the best tools and creating productive, sustainable and effective outcomes for industry.

“Long lead times for large components will be a thing of the past and we can provide faster and cost-effective iterations,” Perissinotto continues. “Our comprehensive approach sets us apart – it’s not just about being faster or cheaper; it’s about providing a complete solution that caters to the entire spectrum of challenges.”

Saeki predicts that its platform that will allow customers to transcend the limits of traditional manufacturing. Size, complexity and efficiency will no longer be obstacles, “but catalysts for progress”, it declares.

The company aims to become the leading technology provider for components ranging in size from 0.2m to 10m or more, using RDM (robotic digital manufacturing) microfactories: self-contained facilities that can perform all of the manufacturing steps. These will be easily deployable to allow localised manufacturing. Saeki will also offer a quoting platform tailored to its customers’ needs, removing the current “complex, opaque” approach.

The company is currently building its first production hub, which will be the blueprint for a network of decentralised, robot-operated production facilities around the world. The hub will use industrial robots built by the company that will combine multiple manufacturing technologies including 3D printing, milling and inspection, using low-waste production process and recyclable materials.

“In 10 years from now, Saeki envisions lights-out factories filled with microfactories autonomously producing complex, material- and weight-saving formwork for the construction industry, fixtures and tooling for supersonic jets, or composite moulds for next-generation Formula One cars,” explains co-founder and COO, Matthias Leschok. “Saeki’s mission is to empower design freedom to be efficient and sustainable – irrespective of the final product.”

The $2.3m funding round was led by Wingman Ventures, a Swiss company specialising in pre-seed funding for tech companies. Wingman’s principal Edouard Treccani believes that Saeki’s “groundbreaking” approach to distributed additive manufacturing “has the power to revolutionise sectors from aerospace to construction through disruptive tech, local production and sustainable materials.”