- Home » News » Product News

Rotating machine monitors help to raise reliability

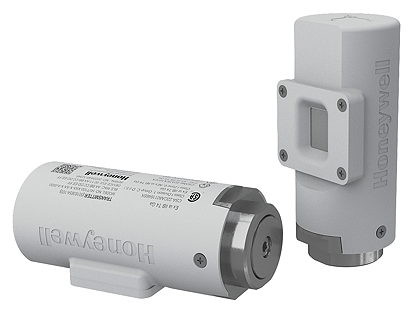

Honeywell has introduced a range of transmitters for condition-based monitoring of rotating equipment such as pumps, motors, compressors, fans and gearboxes, designed to maximise uptime and reliability by providing users with insights into their performance.

The Versatilis transmitters measure vibration, surface temperature and acoustic signals to anticipate rotary equipment problems. They also monitor environmental variables including ambient temperature, relative humidity and atmospheric pressure. When used with Honeywell analytics software, the tranmitters can help to predict equipment problems such as imbalances, misalignments and bearing-related issues before they happen, helping to reduce unplanned downtime.

The transmitters monitor vibrations in both the horizontal and axial planes. High vibration amplitudes in the horizontal plane can indicate potential imbalance issues, while high vibration levels in the axial plane can indicate misalignment and bent shaft problems. If the vibration amplitudes increase, this can confirm the severity of the faults. If frequency peaks occur at fundamental frequencies as well as at two, three or four times the fundamental, this can confirm that an issue is real. Finally, surface temperature trends can identify possible lubrication issues and potential faults due to air-cooling pipelines becoming clogged.

The IP67-protected transmitters use the long-range, low-energy LoRaWan protocol to relay data on equipment health and the ambient environment over large areas. They also incorporate Bluetooth Low-Energy (BLE) communications for quick, reliable configuration and troubleshooting using mobile devices. The transmitters can be integrated with Scada or asset management platforms.

As well as monitoring rotating equipment, the transmitters can also be used to remotely sense valve positions, process equipment surface temperatures, heat exchanger reliability and the health of steam traps.

The batteries in the low power consumption transmitters can operate for up to five years.

“Predictive maintenance through condition-based monitoring is an important digitalisation use case at industrial facilities,” says Achal Nath, a senior director at Honeywell Process Solutions. “By integrating Versatilis transmitters into their operations, companies can utilise data-based equipment health insights to achieve optimal rotating equipment performance.”

Honeywell Process Solutions: Twitter LinkedIn Facebook