- Home » News » Technology News

Belt-driven rival to hydraulic actuators wins US patent

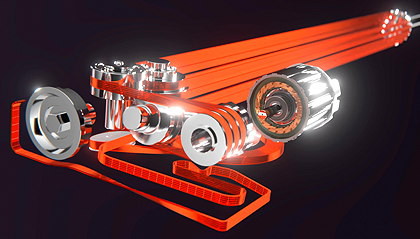

Rise Robotics, the US developer of an electromechanical alternative to high-power hydraulic actuators, has been granted a US patent for its high-reduction, belt-driven linear actuator technology.

The actuators use steel-reinforced polyurethane belts that run around multiple pulleys inside the actuator, driven by an electric motor. US Patent 11,255,416 covers the use of “high-performing flat belts in high-reduction (6:1 or greater) block-and-tackle topologies, with the principal benefits of an extended service life, high power transmission efficiency, more effective traction power transfer, and a compact machine design”.

Rise says it now holds “dozens” of pending, issued or granted patents worldwide. Additional pending US and international patent applications are expected to protect other technologies that the company is developing.

“These belts are capable of operating at pulley interface pressures in excess of 1,400 PSI (965N/cm2) for millions of bending cycles,” says Rise Robotics’ co-founder and chief technology officer, Blake Sessions, who is credited with the invention in the patent. “This new design paradigm contains analogous subsystems to perform all of the functions that a conventional hydraulic circuit performs today. We have constructed power transmission systems that are able to animate a machine's work functions with very high efficiency and without the use of hydraulic oil.”

Rise claims that its fluid-free actuators deliver superior precision, speed, and weight while using up to 90% less energy than hydraulic systems. It also says the 3D technology is more cost-effective and durable than other electromechanical actuators, while providing longer strokes and higher speeds. The high efficiency, combined with physical and functional reconfigurability that can be tailored to an application, “makes the electrification of heavy machinery practical”, the company declares.

The actuators are claimed to cut actuation energy by 65-90%, while halving the total net energy consumed at a system level. The system’s cost is comparable to that of a modern hydraulic system, but it eliminates the need for fluid, reservoirs, pumps, valves, blocks, seals, lines and hoses, as well as cooling systems and maintenance costs. The low-noise actuators can be replaced “in minutes”, without needing to manage high-pressure fluids.

In the past year, the Rise has:

• won a $1.55m contract to supply to supply lifting devices to the US Air Force;

• been awarded a grant from the US Department of Energy to develop a technology (in collaboration with CA Goudey & Associates) that uses its actuators to capture energy from ocean waves;

• signed a collaboration agreement with Danfoss Power Solutions to jointly validate and test an innovation that has the potential to transform the heavy machinery market through electrification; and

• won another award (worth $1.25m) from the US Air Force to design an ultra-light system for loading cargo pallets onto aircraft which will be a fraction of the weight of traditional diesel-powered hydraulic forklifts.

Rise Robotics was founded in 2011 by graduates of MIT (Massachusetts Institute of Technology) and Rhode Island School of Design. It is based in Somerville, Massachusetts.

Rise Robotics: Twitter LinkedIn Facebook