- Home » News » Technology News

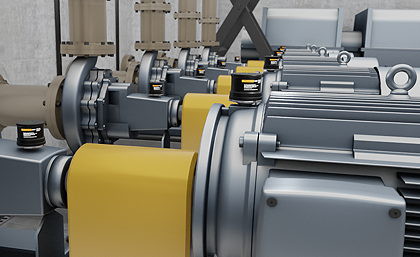

‘Unique’ vibration analysis sensor integrates software

Fluke Reliability has announced a “unique” vibration sensing system that combines hardware and software to analyse a machine’s condition and take appropriate action to avoid downtime, rather than simply screening for problems. The Fluke 3563 vibration analysis system combines a high-frequency piezoelectric sensor, two MEMS (microelectromechanical systems) sensors, and software, allowing maintenance teams to monitor and analyse vibration readings continuously from critical assets in a plant.

Fluke argues that until now it has been difficult or cost-prohibitive to use vibration-monitoring systems to monitor every type of machine in a factory to reduce downtime and prevent potentially catastrophic failures. By combining hardware, software and services, the new system can give detailed insights into anything from performance tracking to fault analysis, thus improving the reliability of equipment.

“The Fluke 3563 vibration analysis sensor is unique in that it combines sophisticated piezoelectric technology with robust software to analyse a machine’s conditions versus simply screening for it,” explains Ankush Malhotra, president of Fluke Reliability Solutions. “This creates a system that recognises each machine’s unique vibration signal to reliably identify the four common faults – imbalance, misalignment, looseness and bearing damage – much more quickly to minimise equipment downtime.”

Users can configure the sensors based on the type of machine being monitored, to generate precise readings without needing to enter severity thresholds manually.

The system has an operating frequency range of 2–10kHz, which Fluke says is up to ten times wider than most vibration sensors. The Live-Asset Portal software can analyse both banded overall values and narrowband values, helping to pinpoint the fault causing a problem. The system monitors two axes to provide detailed information.

The wireless sensors have dual network connection capabilities – Wi-Fi and Ethernet – allowing them to be used in any facility. The wireless capability makes it easier to monitor machines in awkward locations where walk-around checks would be impossible. It also reduces the time and effort needed to collect data. Up to 20 sensors on different machines can transmit data to a single gateway located up to 100m away.

The piezo sensor and software also combine to offer smart battery management, allowing users to determine the data transmission rates, thus adapting and extending the sensor’s battery life, while still capturing the necessary data. If data is transmitted every ten minutes, the on-board batteries will typically power the device for about a year.

“The Fluke 3563 features a unique floating architecture to collect the best possible vibration data, auto-generated thresholds based on asset details, and alarm notifications combined with the analytical software to identify faults that spur quick action,” says Tyler Evans, Fluke Reliability Solutions’ director of product management. “Early warnings of potential asset malfunction ensure there will be enough time for corrective action before a catastrophic failure occurs.”

Purchasers of the new vibration analysis system will get one-to-one set-up assistance from Fluke Reliability experts remotely or on-site, simplifying the configuration, commissioning and installation processes. Various training options will also be available.

In Europe, a system consisting of 16 sensors and two gateways will cost €9,770, including one year's subscription to the software, which will subsequently cost €20 per sensor per month.

Fluke Reliability offers tools, software and services for optimising asset performance, and consists of three brands – Fluke Connect, Pruftechnik and eMaint. It has more than 70,000 customers worldwide.