- Home » News » Technology News

Electrostatic motors ‘will outperform magnetic machines’

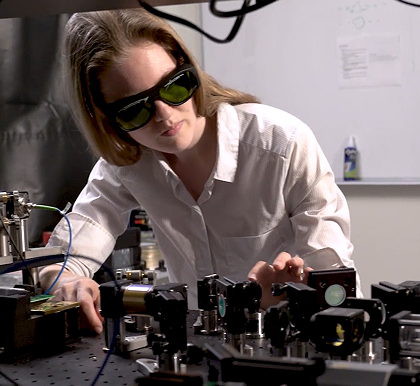

The US engineering innovation company Draper is developing a family of electric motors that operate on fundamentally different principles from conventional motors. It says that the new machines will be more powerful and efficient, lighter, and less expensive to manufacture than standard motors. Underpinning the initiative is a recent patent awarded to Draper that covers aspects of the technology.

The non-profit company, based in Cambridge, Massachusetts, believes that its development will benefit a wide range of technologies that rely on motors, from electric vehicles to drones, extending their range and mobility.

Most existing motors rely on magnetism to generate torque. The weight and cost of materials such as steel, copper and magnets, that are needed to build these motors place limitations on some applications. Draper’s newly-patented approach replaces those materials with thin, lightweight and widely-available materials.

For centuries, engineers have known that forces generated by electric fields can be harnessed to build motors, but these “electrostatic” motors have been considered too weak to compete with electromagnetic machines.

Draper says by using state-of-the-art materials, novel designs and decades of fabrication expertise, its powerful new motors will break through the torque barrier that limited earlier electrostatic designs.

Compared to conventional motors, they will cut weight “drastically”, improve efficiency, reduce material costs and deliver higher specific power. The electrostatic motors will not need rare-earth materials – an important consideration in light of rising prices for these materials and recent reports of a potential ban on the export of rare-earths by China, their main producer.

“Our e-motors use thin electrodes and electrets which reduce weight by 80% or more compared to conventional motors,” says Draper’s automotive business development manager, Sabrina Mansur. “This translates to a range extension of up to 40% for drones, and up to 25% for electric vehicles based on our simulations.”

Draper is also working on generators using similar principles. It is planning to license its technologies to potential manufacturers.

Draper has a workforce of more than 1,800 people, including more than 1,200 engineers and scientists. It uses a multidisciplinary approach to deliver new technological capabilities. It designs, develops and deploys advanced technologies to help solve some the world’s most challenging problems.

Draper: Twitter LinkedIn Facebook