- Home » News » Technology News

Record-setting power converter boosts densities eight-fold

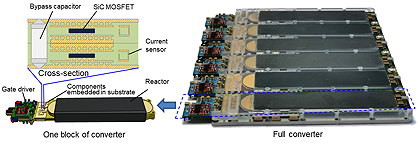

Mitsubishi Electric has developed a new technology that integrates power semiconductor devices, passive devices, sensors and other components in the same substrate, and has used the technology build a 100kW (continuous) bidirectional DC-DC converter with a power density of 136kW per litre – making it the world’s most power-dense converter, with a density eight times higher than conventional converters. The company predicts that the technology will result in much smaller power electronics equipment.

Mitsubishi’s component integration technology allows the parasitic inductance of switching current loops to be slashed to less than 1 nano-Henry – 10% that of conventional converters. This results in clean switching, allowing high-speed commutation for high operating frequencies in silicon-carbide (SiC) Mosfets (metal–oxide semiconductor field-effect transistors). This, in turn, allows the use of much smaller passive components, such as reactors for current smoothing, and capacitors, which usually account for much of the bulk of DC-DC converters.

The switching current loops of conventional power converters exhibit high levels of parasitic inductance because wire-bonds and passive components are located outside of the casing. Switching at high speeds with a large parasitic inductance results in significant voltage oscillations, which can damage power devices and increase noise levels.

To avoid these problems, switching speeds are deliberately limited, but low-speed switching is inefficient because the loss per commutation is large. Also, limiting the operating frequencies makes it difficult to reduce the size of the reactors in power converters.

Mitsubishi’s new technology allows components to be embedded in the same substrate, reducing the parasitic inductance of the switching current loop to less than 1nH. As a result, the power converters can switch at high speeds – a desirable characteristic for SiC devices. Because the converters are operating at high frequencies, the size of the passive components can be shrunk by as much as 80%.

Mitsubishi is hoping to achieve even higher levels of integration by using multi-functional components.