- Home » News » Technology News

Digital twin robot programming slashes commissioning times

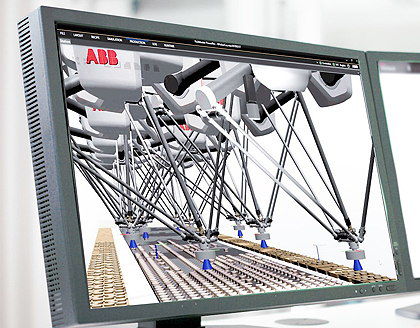

ABB Robotics has announced a new generation of robot programming software which uses digital twin technology for the first time, and is claimed to cut commissioning times from days to hours, and changeover periods from hours to minutes. ABB asserts that its PickMaster Twin software will also reduce picking times by 15% and boost output and line efficiencies by 40%.

The software, which works with any ABB robot as well as “a range of virtual and physical machines”, is aimed at vision-guided, random-flow picking and packing applications – especially where higher outputs, faster response times and quick changeovers are needed. It is claimed to deliver improved flexibility and visualisation for complex robotic manoeuvres used for flow-wrapping, tray-loading, case and carton packing, and handling applications.

The digital twin technology allows users to test out robotic configurations on virtual production lines before they build the physical lines. The simulated twin can connect directly with production operations, allowing picking processes to be optimised virtually at the same time as the process is being implemented.

Allowing picking and packing tasks to be programmed offline means that users can create, simulate and test complete robot installations in a virtual environment without having to disturb their real production lines. This not only helps to reduce costly and time-consuming risks, but also shortens the time-to-market for new products, because product lines can be installed faster, ramped up to full speed without surprises during commissioning, and optimised continuously – helping manufacturers to achieve mass customisation and shorter product lifecycles.

Intuitive new interfaces based on ABB’s Ability Zenon Operations Data Management platform provide colourful dashboards for easy data visualisation. The software also complies with the OMAC PackML (packaging machine language) standard, making it suitable for modern packaging machines. The software also allows workspaces to be tuned visually online in both the X and Y directions to maximise output and increase OEE (overall equipment effectiveness).

Steven Wyatt, head of portfolio and digital for ABB’s Robotics & Discrete Automation business, predicts that the new software “will help our customers take high-speed picking and rapid applications to the next level, whether it’s to boost picking and packing efficiency, or to reduce the cost of integrating robotics into production lines”.