Hannover Fair 2019 Exclusive Show Report

An inescapable theme at this year’s Hannover Fair was the emergence of 5G as potential game-changer for industrial communications. The high-speed, low-latency technology could oust traditional signal wiring in many applications – although widespread adoption still seems several years away.

The 2019 Hannover Fair drew 215,000 visitors to the Northern German city in April – a slight increase on last year’s total. The event is attracting increasing interest from outside Germany, with nearly 40% of the visitors coming from abroad – a significant increase on the 30% at the 2018 event.

China once again contributed the largest number of foreign delegates with 7,200 of its citizens travelling half-way around the world to be at Hannover, followed by the Netherlands (5,900), Italy (3,400) and the US (3,400). There were around 6,500 exhibitors for them to see (up from 5,800 in 2018).

In terms of technologies, artificial intelligence (AI), robotics, virtual/augmented and machine learning were widespread themes, with the show’s organisers estimating that there were more than 500 demonstrations of the use of AI in manufacturing.

Photo: Hannover Messe

Perhaps the biggest buzz was around the potential for high-speed, low-latency 5G communications in industrial applications. If it lives up to the hype, 5G could eventually replace traditional signalling cables, saving time and money and making it much easier to re-arrange factory layouts when needed.

At Hannover, Nokia and Qualcomm were demonstrating a 5G test environment, while Ericsson and ABB signed a memorandum of understanding (MoU) outlining a joint vision for future flexible production based on advanced automation and communication technologies. The two companies are already researching 5G and IIoT technologies, and, according to Ericsson’s president, Börje Ekholm, the MoU could lead to them “unlocking new business opportunities enabled by combining 5G and Industry 4.0”.

It seems that 5G could have a major impact at the 2020 Hannover Fair. Over the coming months, Hannover will become the world’s first trade show venue to be equipped with 5G. “Next year’s fair will feature numerous applications for 5G technology,” predicts Dr Klaus Mittelbach, CEO of Germany’s ZVEI industrial trade association. “Together with artificial intelligence, it’s going to be an important competitive factor.”

Although it could take two more years to standardise 5G for industrial applications, this could lead to the emergence of 5G chips that equipment suppliers can embed in their products – a potential turning point for the technology.

Over the next few pages, we highlight some of the products and technologies that were on show in Hannover this year.

DRIVES AND MOTORS

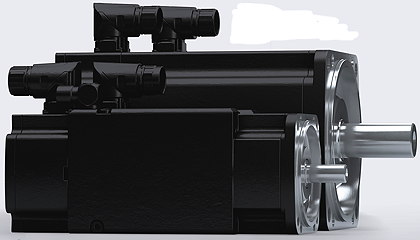

Baumüller has expanded its servomotor portfolio with a pair of water-cooled models (sizes 45 and 56), claiming it is the only manufacturer to offer small servomotors with a choice of cooling methods. The high-power-density water-cooled models (shown below) save space and allow relatively small motors to achieve high nominal powers. They also avoid the need for fans.

Beckhoff announced an IP65 power supply module for its AMP8000 distributed servodrives that allow complete drive systems to be built into or near machines, saving space, costs and work. Previously a single cable was needed to link the drives to the control cabinet; now, even that can be eliminated, as well as air-conditioning in cabinets. The AMP8620 module is connected to the mains and includes filters, rectifiers, two EtherCat P outputs, and charging circuits for the built-in DC link capacitors that can store regenerative energy.

The Taiwanese manufacturer Delta was showing a heavy-duty drive that provides open- and closed-loop control of synchronous and asynchronous motors up to 560kW at 460V. The C2000 Plus vector control drive offers speed and position control and incorporates a PLC capable of up to 10,000 steps.

Lafert, the Italian motor-maker now owned by Sumitomo, expanded its range of IE4/IE5 permanent magnet motors by adding a frame 56 model and extending its frame 160 motors up to 37kW. It has also re-engineered its HPI family of PM motors with integrated drives starting from frame 71 which is now available in a single-phase version.

As we have reported previously, Mitsubishi used the Hannover Fair to introduce 690V versions of its FR-A800 series of inverters in ratings up to 1.5MW. Versions of the FR-A870 drive up to 200kW have built-in brake choppers to reduce deceleration times, eliminating the need for external brakes. The 690V drives are initially available in ratings from 160–200kW, and will eventually span ratings from 37kW–1.5MW.

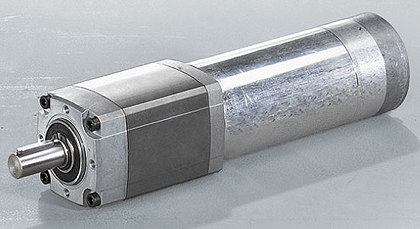

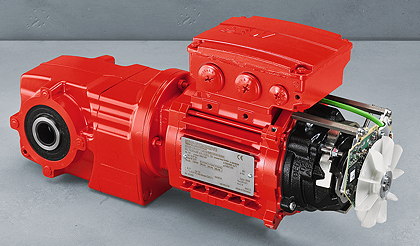

SEW-Eurodrive unveiled a series of compact, electronically-commutated ELV (extra-low-voltage) gear-motors (above) in ratings from 188–357W at 48V DC. The interior-rotor motors from the DCA series offer high power densities and dynamics and can be configured locally. The family includes versions with planetary and right-angle gearboxes which can be supplied with single-disk brakes that are powered and controlled via the drive electronics. The gear-motors are aimed at applications such as conveyors.

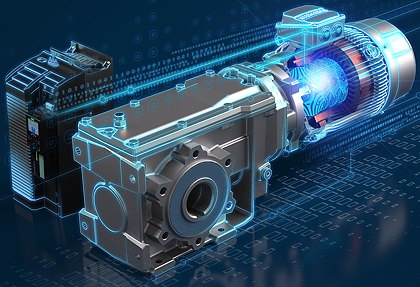

Siemens has extended its Simogear geared motor portfolio to include synchronous reluctance versions with outputs from 0.55–4kW. Efficiencies are said to be “comparable to IE4”, even under partial loads. The cool-running drives (below) offer high dynamics due to their low moments of inertia. To commission the drive, you simply enter the motor code into the converter. External fans are not needed due to the constant torque/speed curve up to nominal speed.

Weidmüller has added a multifunction stepper motor module to its u-remote family. The UR20-1SM-50W-6D12DO-P module can be used to automate stepper motor applications, simply and flexibly. It has a built-in power amplifier for controlling two-phase steppers up 50W, delivering 2A at 24V DC. The 23mm-wide module has six parameterisable digital inputs and two 0.5A digital outputs for controlling actuators.

CONTROLS

ABB has a new version (6.1) of its System 800xA DCS (distributed control system) which has a flexible Ethernet-based, single-channel I/O system, and a new workflow that will speed up projects and allow tasks to be done in parallel. The Select I/O system is claimed to shorten commissioning times, and allows standard, pretested cabinets to be connected directly to field devices, saving on patch panels, drawings, equipment and labour. Real-time information on power consumption is available down to individual loads.

Beckhoff has extended its family of ultra-compact industrial PCs with a new model (above) that adds an extra PCB level and offers a modular interface. The C6032 IPC measures 129 x 133 x 104mm and is available with processors up to Core i7 with four 3.6GHz cores. Two PCIe module slots can accept modules containing pairs of Gbit Ethernet, USB 3.0 or RS-232 ports.

B&R Automation is now offering its Power Panel operator panels for swing-arm mounting (below). The IP67-protected T50 Field HMI terminals are available in five widescreen sizes from 5–21.5”, in depths of 16.5 or 26mm. Power-over-Ethernet connections mean that one cable can carry both power and communications. The multi-touch panels support gestures such as swiping and zooming.

Following Delta’s cooperation with Codesys announced last year, it was demonstrating a Codesys-based motion control system which complies with IEC 62231-3 and allows PLCs, HMIs and motion controls to be combined in a single platform that uses EtherCat to control field devices. Delta was also showing a PLC-based motion controller (the DXMC) with an optional Codesys Soft-PLC, which can synchronously control 32 axes in a standard version, or eight in a panel-mounting version.

Lenze presented its next generation of cabinet controllers, the c500 series, with powerful processors for tasks with high demands in terms of computing power. One model splits this power between a control component and an encapsulated Windows 10 IoT operating system which, with the aid of the OpenSystem architecture, can execute Windows applications such as AI, 2D and 3D code detection, and vision system analyses. It can also process and compress data for the cloud, or for uses such as predictive maintenance.

Phoenix Contact announced a series of expansion modules for its PLCnext Control controllers. The first provides an extra Ethernet interface with an additional MAC address, while future modules will support Interbus and Profibus, offering master functions to connect to existing devices. The modules are configured using the PLCnext Engineer software.

Siemens unveiled an extremely powerful industrial PC which comes with up to two Intel Xeon processors, each containing up to 14 cores. The rack-mounting, metal-enclosed Simatic IPC1047 PC can run several demanding applications – such as visualisation and machine learning – simultaneously, and can drive several screens using up to two Nvidia Quadro P5000 graphics processors.

At the less powerful end of Siemens’ IPC portfolio, its new IPC527G PC comes in a compact format with a choice of mounting options. It is equipped with Intel Core i5 or Pentium processors, and supports up to 32Gb of memory. There are three Gigabit Ethernet interfaces and four PCI/PCIe slots.

Siemens has also implemented an OPC UA interface which supports the Omac PackML packaging machine language in its Simatic S7-1500 controller. This is based on a specification drawn up by OPC and Omac members and will make it easier to integrate packaging machines and to connect them to MES and other systems. The integration can be programmed automatically, avoiding the need for manual coordination between machine manufacturers and line integrators.

ELECTRICAL AND SAFETY

Euchner was demonstrating an enhanced version of its MGB multifunctional gate box which, instead of using bus communications, connects directly to control systems, making it suitable for non-networked machines that are wired in parallel. The MGB2 Classic (below) has two OSSD outputs, and provides continuous diagnostics information via a LED indicator. Up to ten devices can be connected in series.

Euchner also has a new transponder-coded door-locking mechanism for use on small doors and flaps. The compact (120 x 36 x 25mm) CTM mechanism has a bistable locking function that remains in the same state if the power fails or an installation is switched off. This prevents people from being locked in if the power fails.

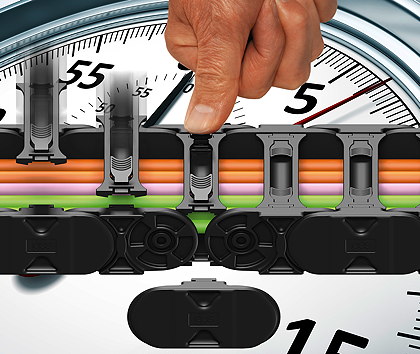

Igus showed a prototype of a new type of energy chain aimed at demanding applications with long self-supporting lengths and travel distances. The links of the E4Q chain (below) have a novel “pebble-shaped” design and a lightweight opening bar with locking straps which can be opened and closed “in seconds” without any tools. Igus says that this design will reduce the time needed to fill e-chains by up to 40%.

Phoenix Contact claims to have developed the first “intelligent” assistance system for surge protection components, which performs real-time measurements of electromagnetic interference and surge currents to record the condition of surge protection devices continuously. The ImpulseCheck system uses cloud-based analysis to determine the remaining life expectancy of the devices, and to create status reports and, if necessary, to order replacements.

Phoenix has also developed a liquid-metal-based shielding technology for connectors which, it says, improves the transmission quality of data, signals and power, even under extreme conditions. The process creates a complete braided shield and conductor assembly (shown below) with a large area that reduces heating, even in the event of a short-circuit. The shielding is resistant to shocks, vibrations and transient overvoltages caused by inductive switching.

Finally, Phoenix was showing a new series of terminal blocks with side conductor connections which are said to allow clear wiring without bending in tight spaces. The PTV blocks are available for wires with cross-sections up to 4mm2, and in feed-through, three- and four-conductor versions. Tool-free push-in connections save time.

Pilz’s PSENscan safety laser scanners (below) can now be used for vertical guarding applications such as access protection. Muting inputs mean that the scanners can monitor conveyor applications where materials are simultaneously transported in and out, without slowing the conveyor. Master and slave versions can monitor up to 70 switchable configurations and three zones simultaneously, while four scanners can be connected in series, reducing cabling and set-up work.

Pilz’s PNOZ s60 safe voltage monitor can now monitor de-energised plant to UL 6420, making it suitable for SLS (safety lockout system) applications in the USA. The 90mm-wide monitor monitors de-energised single- or three-phase supplies with neutral conductors, and allows 6V or 12V thresholds to be set.

Wago announced several enhancements to its portfolio of terminal blocks, including: a new model for its X-Com S-System pluggable rail-mount blocks that allows both inputs and outputs to be plugged in, making connections “in seconds”; an expansion of the tool-free, lever-actuated Topjob S rail-mount blocks, adding 10mm2 blocks in two- and three conductor models (to the existing 6 and 16mm2 versions); a series of button-actuated disconnect/test and fuse terminal blocks modelled on the Topjob S range and accepting 2.5mm2 conductors; and a pushbutton version of the Topjob S double-deck terminal block family, making them easier to wire in small boxes.

Wago also has a new family of power supplies in six sizes from 120–690W, with snap-on comms modules for IO-Link, Modbus RTU and TCP, and other bus systems. The Pro 2 supplies allow parameters such as output voltage and overload behaviour to be configured via software. They offer efficiencies up to 96%, and can boost their output current by 600% to provide protection for up to 15ms, or by 150% for five seconds, eliminating the need for oversizing.

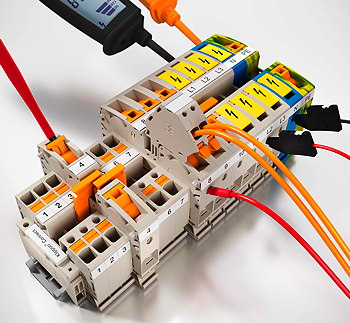

Weidmüller has expanded its A series Klippon Connect terminal blocks to include the new A2C 35 family of high-current terminals for wires with cross-sections up to 35mm2 (shown below). They use push-in connections with an actuation lever to make connections “in seconds”. Variants include rail and direct mounting, as well as pre-assembled feed-in blocks for various network technologies.

MECHANICAL, ROBOTICS AND LINEAR

Two six-axis robots from Mitsubishi Electric’s RV series, with maximum load capacities of 7kg, have been certified for use in hazardous areas. No modifications were needed to the IP67-protected robots to achieve Ex protection class II 3G c IIB T3 Gc certification, so they can be supplied without extended lead times. A new chapter in the robots’ operating instructions covers their use in hazardous areas.

Mitsubishi has also produced a plug-in expansion card which adds predictive maintenance functions to its FR series Scara robots. The SmartPlus card includes functions such as optimised temperature compensation for improved positioning accuracy. The card can retrieve data from the robot’s servomotors to indicate potential failure risks – such as damage to the motor, or gears or bearings on the same shaft, or signs of wear.

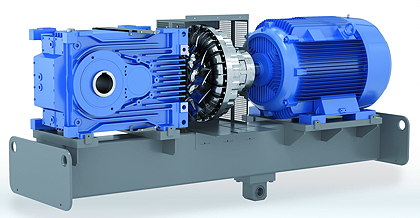

Nord DriveSystems was demonstrating a range of two-stage angled gearboxes for applications requiring low speed ratios and high power ratings. The Maxxdrive XT gearboxes (below) come in seven sizes, with power ratings from 50–1,500kW, output torques from 15–75kNm, and speed ratios from 6.3–22.4. They have built-in axial fans and, in many cases, no extra cooling is needed.

Bosch Rexroth was previewing an autonomous transport system for factories which can move loads of up to 250kg on dollies equipped with “small load carriers”. The ActiveShuttle dollies are loaded and unloaded automatically using a built-in lifting platform. The “plug-and-go” system can be integrated rapidly into existing infrastructures without needing to make any changes. The system is due to go on sale in the fourth quarter of 2019.

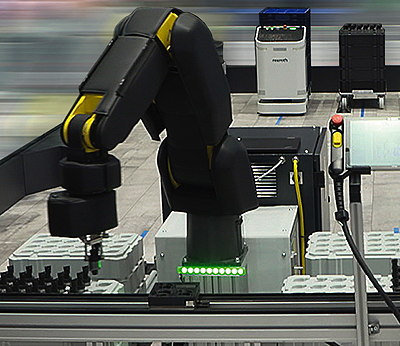

The ActiveShuttle can also be used with another Rexroth technology, called the Apas inline assistant – a collaborative robot designed to be integrated into production lines and to close the gap between AGVs and line transfer systems. The robot (shown below, with an ActiveShuttle dolly in the background) has a built-in camera that can track products and to ensure that items are gripped and recorded reliably. This makes continuous material flows possible, and closes the gap between the ActiveShuttle and Rexroth’s transfer systems.

Schaeffler unveiled a concept that will allow gearbox manufacturers to cut costs by using interchangeable modular components such as bearings with the same external dimensions. The interchangeable bearings are aimed, initially, at precision servo planetary gearboxes and include deep-groove and angular-contact bearings, allowing load capacities, speed ranges and rigidity to be adjusted within the same envelope.

Schaeffler also announced a re-usable cover strip for its profiled guide rails which, it claims, will cut assembly times by up to 90%. The ADE steel cover strip – for the RUE 35, 45 and 55 assemblies – slides into a groove in the rail and is fixed in place by a screw. Another new guide rail timesaver is a range of patented plastic closing plugs which allow several plugs to be driven into place in one step, cutting mounting times by up to 75%. The KA-TN/B plugs are simply inserted into the bore and driven in until they are flush with the surface, at which point an attached clinch ring breaks loose.

Schunk was previewing a new gripper for collaborative robots which, it says, will “shatter” the applied gripping force limit of 140N by using an “intelligent” safe gripping process involving more than six safety functions – more than any other gripper. The Co-act EGL-C, (below) which is due to be launched by the end of 2019, will be able to handle workpieces up to 2.25kg.

SEW-Eurodrive has expanded its range of gear oils to include synthetic polyglycol oils that lubricate gears reliably, even under heavy loads, as well as improving efficiency and extending the service lives of parts such as sealing rings. The GearOil Poly oils come in three viscosity classes and an H1 food industry version. They can be used in potentially explosive atmospheres.

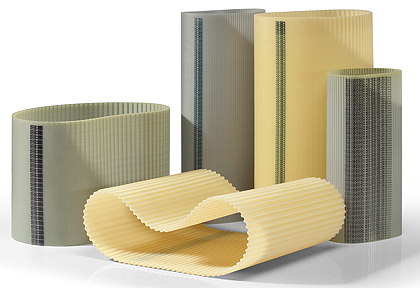

The German belt-maker, Steigentech, launched a range of polyurethane timing belts with the claim that they out-perform rival products by up to 30% in terms of wear resistance and strength. The Powerplus PU belts (below) are said to be a cleaner alternative to rubber belts, and to offer good abrasion and shear resistance, as well as elasticity and flexibility. Steigentech also has a new range of CRE (cogged raw edge) V-belts that can be installed easily and do not need re-tensioning, maximising uptime and reducing maintenance. The Powerplus EPDM CRE belts incorporate high-tensile cords to improve efficiency.

Yamaha’s factory automation division was demonstrating a range of robots that can handle payloads from 5–50kg. It claims it is the only manufacturer to offer a choice of four common robot technologies: Cartesian; Scara; single-axis; and multi-axis articulated. The portfolio includes clean-room, dust- and drip-proof and high-speed pick-and-place models. They can be used with bidirectional linear conveyor modules said to overcome the restrictions of conventional belt-and-roller transport systems.

SENSORS, MEASUREMENT AND DIAGNOSIS

ABB was demonstrating how its Ability digital powertrain condition-monitoring system can help users of equipment such as pumps and fans to gain a better insight into their operation. A built-in portal can be used to visualise operating variables, status indicators, availability, environmental conditions and faults.

At Hannover, the Italian automation specialist, Gefran, launched a magnetostrictive position transducer that, it claims, offers a repeatability of 0.01mm, a resolution better than 0.5µm, an amplification 15 times higher than traditional designs, a high tolerance of vibrations and shocks, immunity to electromagnetic fields, and an operating temperature range from –30 to +90°C. The IP67-protected Hyperwave contactless transducer is almost wear-free and is available in direct-mounting or rod-style versions.

Pepperl+Fuchs has a new family of inductive safety sensors in various cylindrical and rectangular formats, including flush and non-flush mounting versions. The TÜV-certified (to PL d Cat 2 / SIL 2) sensors (below) do not need coded targets and can be used with standard metal actuators. There are no blind zones and the sensors have OSSD outputs for signals and diagnostics.

P+F was also demonstrating a cloud-based system for monitoring production equipment. It uses RFID readers to identify assets, data from which is sent via a gateway to the Neoception Cloud, where it can be viewed at any time from anywhere, making it easier to plan production processes.

Schaeffler has a new generation of its ProLink multi-channel condition-monitoring system that requires no expertise to set up signal recording and vibration analysis functions to detect potential problems with bearings, gearboxes, motors, fans and pumps. With the help of a configuration assistant, the user inputs basic data about the components with “intelligent templates” filling in the rest of the information.

SEW-Eurodrive has revamped its modular encoder system consisting of built-in and mount-on encoders. The IP66-protected EI8C and EI8R encoders are designed to be built into or retrofitted to motors and comes in sizes 71–180. They have HTL and TTL interfaces and 1,024-increment resolutions. The updated EK8C, EK8R, EK8S, AK8W and AK8H sin/cos encoders (below) mount on a motor behind the fan and offer HTL and TTL, and SSI or Hiperface interfaces. Brake wear can be measured without having to disassemble the encoder.

Weidmüller is offering a load-monitoring system which uses IO-Link to provide communications between machines, control cabinets, IT systems and the cloud, thus offering new control, monitoring and analysis options. The topGuard system can also be used to protect 24V systems and has built-in potential distribution which saves space and installation time.

COMMUNICATIONS, IoT AND THE CLOUD

Controllers from Mitsubishi Electric’s Melsec FX5, L, QnA and iQ series can now be connected to higher-level systems via an enhanced version of the DIN-rail-mounting IBH Link UA module which acts as an OPC UA server/client modules with a firewall. The module has four Ethernet ports and a 24V power supply and can exchange user-defined OPC UA variables with an MQTT broker, thus linking it to the cloud. It will soon be possible to connect Mitsubishi robots with OPC UA CS as well.

Murrelektronik was demonstrating a Profinet/ProfiSafe module that combines digital sensors and actuators, safety digital sensors and actuators, and a pair of IO-Link ports. Configuration can be done using engineering tools in safety control systems, and installation is said to be fast and easy, with fewer fieldbus modules needed. Safety sensor signals are transmitted via three two-channel safe input ports, while the safety output port has two configurable safe outputs.

Following its recent acquisition of US-based Comtrol, Pepperl+Fuchs has enhanced its IO-Link range to help users improve dataflows from field devices to controls and the cloud. P+F is also using the acquisition to reinforce its Sensorik 4.0 offerings – in particular, managed and unmanaged switches, and interface converters for connecting existing installations to IoT devices such as IO-Link masters.

One example of the enhanced range is a 30mm-wide, multiprotocol IO-Link master with an M12 power connector and a built-in Web server. There is also one IO-Link hub with ten digital inputs, six digital outputs, and another with 16 freely-configurable digital I/O. Finally, there is an IO-Link signal tower that can combine up to five signalling elements.

Phoenix Contact has extended its FL Network Manager software to include topology representation (enabling device connections for each network port to be visualised and checked) and SNMP scripting (enabling deeper diagnostics to be performed on network structures). Version 3.0 of the software can check whether the actual network structure corresponds to the planned structure, and can show at a glance the roles of individual ports and devices in a redundancy system.

Siemens launched a new version (2.0) of its Sinetplan tool for planning and simulating Profinet networks, which allows configuration data for a planned plant to be imported from ECAD (electronic computer-aided design) systems or its TIA selection tool using the AutomationML data exchange format. Siemens says that the tool provides a transparent, virtual representation of planned networks and offers opportunities for optimising them.

Softing was demonstrating a gateway that connects Profibus PA and DP devices with Profinet controls. The pnGate PB (above) allows devices with up to two Profibus PA segments and one DP segment to be controlled via Profinet without needing a DP/PA coupler. Softing was also demonstrating a prototype system (called smartLink PN) that allows asset management and diagnostics data to be accessed from Profinet devices via OPC UA. It is due to be released at the end of 2019.

SOFTWARE

Baumüller has added a simulation tool to its ProDrive commissioning software, allowing users to design and optimise automation and drive systems for machines and to test settings without needing to build a prototype, thus saving time and money. The ProSimulation tool (below) has a graphical interface and can import models from other simulation tools. Once a machine has been commissioned, the software can be used to optimise and troubleshoot the machine.

Baumüller has also added a co-ordinated motion library to its ProMaster engineering framework software, reducing the time required to program motion systems with up to three axes by as much as 80%. The 3D-Axis library includes numerous modules tailored to elementary machine functions and including, for example, visualisation. They can provide functions such as coupling of axis groups, collision monitoring, tool management and geometry compensation.

Beckhoff has added support for OPC UA communications to the TwinCat Scope tool that forms part of its TwinCat 3 engineering software, allowing data to be analysed from sources such as TwinCat controllers and third-party components. The Scope tool (below) provides graphical displays of signal curves as well as data-logging functions. OPC UA allows it to acquire and display data in a vendor-independent way. Beckhoff has also added OPC UA support to its TwinCat Target Browser which is used to manage connected data sources, allowing it to browse connected OPC UA servers.

On a 220-inch video wall, Delta was demonstrating elements from its IIoT-based Digital Factory Monitoring suite which provides a “360-degree view” of manufacturing operations, including data collection, a Scada facility, and energy consumption.

Delta’s DIAStudio integrated engineering software saves time when setting up machinery systems, performing tasks such as selecting, programming, machine tuning and HMI integration using Delta’s PLCs, servodrives, HMIs, VSDs and motors. DIASelector (available for PCs or Android devices) selects machine elements which can be exported to Eplan for project planning and configuration, and then imported into Delta’s DIADesigner to execute programming, parameter setting and management. Finally, the DIAScreen tool offers tag sharing between PLCs and HMIs.

Eplan and Festo were showing how their technologies can be used together to shorten maintenance reaction times. In their Productivity Master demonstration (below), a simulated plant malfunction was signalled on Festo dashboards and communicated to maintenance personnel using Eplan’s Syngineer communications, allowing them to view the current status. Details of the appropriate documentation could be viewed via Eplan’s recently launched eView software.

Iconics, the software developer recently acquired by Mitsubishi, was demonstrating how its new Digital Twins for Manufacturing software, based on Microsoft’s Azure digital twin platform, can save time and resources, and boost productivity and quality. It works with Iconics’ IoTWorX software to perform real-time visualisation, collection and analysis of data from manufacturing equipment or IoT sensors, giving operators insights into the health of their plant, and comparing equipment, facilities or shifts.

Siemens announced a new version (6.0) of its flagship XHQ Operations Intelligence software with enhancements including edge support and a new HTML5-based Web browser client which avoids the need to use a Java browser plug-in. The new version also simplifies the integration of engineering data from Siemens or third-party sources.

The next Hannover Fair will take place from 20–24 April, 2020.