UK start-up uses robots to build homes in microfactories

A UK start-is using robotic microfactories to build affordable, low-energy timber homes. London-based AUAR (Automated Architecture) plans to use the robots to tackle skills shortages, boost sustainability, and improve health and safety in a global network of local microfactories which will build energy-efficient, affordable buildings from sheet timber.

AUAR is the brainchild of two architects, Mollie Claypool (CEO) and Gilles Retsin (CTO/chief architect), who have worked for more than 10 years on robotics, automation, construction and architecture. The company has just completed a £2.6m seed round led by the AI fund Miles Ahead, with ABB Robotics & Automation Ventures being among the investors.

AUAR’s believes that its approach answers many of the challenges facing the building industry, such as supply chain issues, project delivery, quality and skills shortages.

Conventional buildings consist of thousands of different components shipped from around the world, making it almost impossible to automate their construction. AUAR’s goal is to work with one type of material – wood – and one type of machine, dramatically simplifying the supply chain.

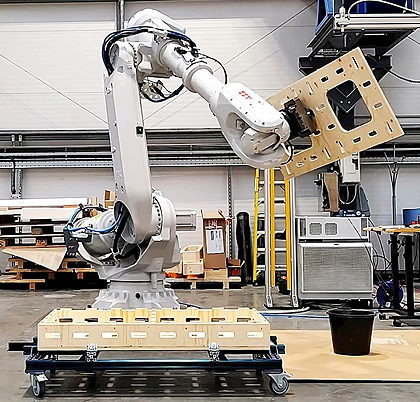

The production process uses standard sheets of timber. A robot cuts the sheets into components and assembles them into modules that are transported to site, allowing customised homes to be built in a matter of weeks.

While many of the assembly tasks are automated, AUAR’s approach supports local jobs by promoting the use of microfactories close to construction sites, where local contractors and suppliers coordinate delivery. Each factory can be scaled to meet local needs, with the ability to ramp up production by adding more modular robot cells.

ABB is supplying the robots for AUAR’s microfactories, while AUAR has developed its own gripper technology. So far, there is one microfactory operating in Belgium and another is planned for the US. AUAR plans to licence its technology to construction firms.

A recent ABB survey of building firms found that 38% of them see robots as a way of cutting waste.

“The increasing capabilities of robots enabled by vision and AI, coupled with their inherent speed, flexibility and consistency, makes them the ideal solution for meeting the growing need for affordable, high quality, sustainable housing,” says Craig McDonnell, managing director of ABB Robotics’ industries business. “With the focus on the dual needs of building more affordable homes and minimising the environmental footprint of buildings throughout their lifetime, automated modular construction presents a great opportunity to rethink the way that the buildings are constructed.”

AUAR: LinkedIn

ABB Robotics: Twitter LinkedIn Facebook