Cheshire plant builds conveyor drives for the global market

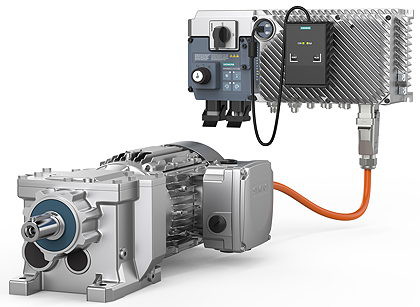

Siemens’ UK drives factory in Congleton, Cheshire, has started to produce a new distributed drive system targeting the global conveyor market. The G115D inverter, announced late last year, is being produced in wall- and motor-mounting versions which users can specify via an online configurator, along with matching motors and gearboxes, to tailor the drives for their applications.

“We have put together a system in which we can ready the product for delivery in just 15 working days,” reports Rob Matthews, who leads the Congleton plant’s supply chain management activities. “If the customer orders a motor-mount version, the inverter is made here, and then shipped to our sister factories in the Czech Republic or Germany to be married with the gearbox and the motor.”

“It has been a challenging, but rewarding, journey getting the G115D ready for the market in the face of Brexit pressures,” adds Gary Wilcock, UK motion control product manager for Siemens Digital Industries. “We are delighted to announce that we now have a nine-month production capacity of 11,000 units.

“The markets we are targeting include logistics, food and beverage, automotive and airports. Of these, logistics and food and beverage sectors are our prime focus areas,” he adds. “The G115D sits nicely as a decentralised drive for these industries. But we are not trying to limit ourselves, because our products offer multiple applications, and we are competent to customise our products to different sectors.”

The compact, IP65-protected drives come in ratings from 0.37–7.5kW for the wall-mounting versions and 0.37–4kW for motor-mounting. They can be used with Siemens’ Simatic S7-1200 PLCs or ET200 motion controls. The drives are integrated into the company’s MindConnect portfolio and are compatible with its Mindsphere cloud-based applications, including Analyze MyDrives.

The Profisafe-supporting drives offer integrated safety in the form of STO (Safe Torque Off) SIL2. They can operate in temperatures from –30 to +55°C.