Strategy aims to put manufacturing at heart of UK economy

The first detailed analysis of the impact of the Covid-19 pandemic on UK manufacturing estimates that it could cost up to £35.7bn in GVA (Gross Added Value) this year, and predicts it will take until 2022 for manufacturing to recover to pre-Covid levels. The report, produced by Make UK and Santander UK, also analyses the opportunities for building a new economy with a renewed manufacturing sector at its heart.

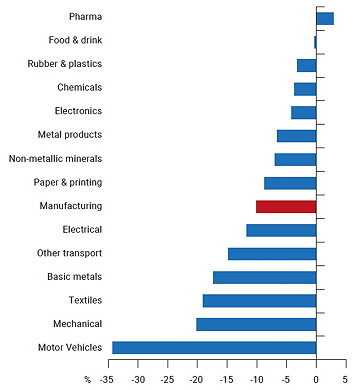

Called Responding, Re-setting and Re-inventing UK Manufacturing Post-Covid, the report highlights how quickly manufacturers responded to the crisis – for example, setting up lines to produce personal protection equipment – but it also predicts that manufacturing output will fall by 9.7% this year, with investment declining by 1–9.7%. By 2022, the GVA will still be £6.8-16.5bn lower than pre-Covid forecasts, it suggests.

Although around 90% of UK manufacturers have continued to trade during the crisis, a quarter are planning to make redundancies in the next six months, the report says. Almost 40% believe that it could take at least 12 months to return to normal trading conditions, but just over a quarter expect to return to full operating levels by the start of 2021.

The report emphasises the importance of manufacturers diversifying their customer base to help achieve growth, maintain demand and avoid over-reliance single markets or customers.

It also looks at the impact of the disruption to supply chains and logistics management, revealing that 31% of small companies and 65% of large companies have been sourcing their components from China or other affected countries.

The report says that there is a desire to reduce risk and build resilience by reviewing supply chains, with more than half of companies (53%) already reviewing them, and a further third planning to do so in the coming year. It argues that this shift will be vital in helping Government to understand critical sectors and components that will be needed to make the economy more resilient.

Looking forward, the report analyses the opportunities for building a new economy with a renewed manufacturing sector at its heart. In particular, this will require industry to embrace the need for digital skills and to rethink existing systems and processes, especially with the use of green and sustainable technologies. According to Make UK, it should be a strategic priority to create a National Skills Task Force.

The report predicts that the manufacturing sector will be at the forefront of helping the UK meet its net-zero carbon target through a combination of investing in green, sustainable processes, and maximising the use of digital technologies. But this can only happen if there is a re-purposed industrial strategy involving a partnership with Government and other stakeholders that recognises the value of manufacturing to the future of the economy and all regions of the UK.

“History has shown us that a strong industrial base provides the foundations needed to create a prosperous society,” says Make UK’s CEO, Stephen Phipson. “However, the UK has unfortunately become culturally tone-deaf to the idea that manufacturing matters and can provide solutions to the challenges that we face, something the sector has aptly shown during this crisis.

“A new digital, greener and more sustainable economy will emerge from this,” he predicts, “with an opportunity to catapult manufacturing, science and engineering once again to centre stage in the UK.”

The report also stresses that embracing technological change will help manufacturers to prepare for the new international trading environment they will face both post Covid-19 but also outside the EU. This will help them to take advantage of new markets and trading opportunities, possibly without having any physical presence on the ground.

The report sets out a raft of proposals for reviving the UK’s manufacturing sector. It argues that the government needs to:

• Recognise manufacturing as a critical sector for the UK economy and should aim for the UK to be one of the world’s top five manufacturing nations.

• Put manufacturing at the heart of the regional economic recovery.

• Work with the sector to map out a global supply chain resilience programme, agreeing coordinated action with partner countries to maintain trade flows and remove administrative restrictions.

• Help manufacturers to move goods, products and services with ease through smart supply chains and global logistics.

• Offer incentives to ensure that industrial R&D capacity and spend are safeguarded.

• Roll out the Made Smarter Review approach to SME digital adoption nationally, with simplified funding.

• Encourage manufacturers to lead the green revolution by making grant schemes simpler, fewer and more accessible for SMEs. Upfront investment costs, it says, remain the biggest barrier to implementing energy efficiency.

• Develop a National Skills Taskforce to meet the skills needs for the future

• Ensure that skilled employees who will be leaving UK manufacturing are matched with demand, including opening up opportunities for those skills to be transferred into other sectors where they are needed.

• Support employees to identify jobs where their skills have relevance and crossover both within manufacturing and more widely.

• Develop an upskilling programme for employees to develop the digital skills needed for the new economy.

The report compares the impact of Covid-19 on the UK with other manufacturing nations, including the US and Germany. It also includes ten case studies describing the actions taken by UK-based manufacturers, including Schneider Electric and Autocraft, to overcome the challenges of Covid-19.

“Our manufacturers are the beating heart of the UK economy, and although sobering, this detailed analysis is vital to understand how businesses can rebuild as restrictions are eased,” concludes Paul Brooks, Santander’s head of manufacturing. “While Covid-19 presents the most testing time for manufacturers at both ends of the supply chain, their aptitude to handle shock and change for the better is enduring, and we stand ready to support them.”