- Home » News » Product News

Efficient motors comply with new Ecodesign Directive

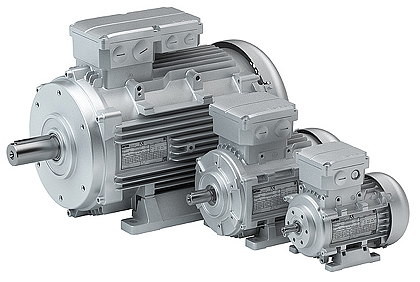

The German drives and automation specialist Lenze is launching a new motor platform that complies with the Ecodesign Directive that is due to come into force in Europe in the summer of 2021. The m500 motors are designed to be future-proof and can be used worldwide. They are intended primarily to be combined with Lenze’s g500 gearboxes and i500 inverters.

The modular three-phase AC motors include IE2 high-efficiency motors (m550-H) covering the power range 0.12–0.55kW, and IE3 premium-efficiency machines (m550-P) covering the power range 0.75-22kW. Connections can be made via a terminal box or plug connectors for fast commissioning.

From 1 July, 2021, the Ecodesign Directive – also known as the ErP Directive – will impose new minimum efficiency levels for electric motors, as well as reducing the number of exceptions. Electric motors used in machines sold in Europe will have to meet the higher efficiency requirements.

The Directive will apply to induction motors without carbon brushes, commutators, slip-rings, or electric rotor connections, designed for operation at a sinusoidal voltage, that also:

• have two, four, six or eight poles;

• have a rated frequency of 50Hz or 60Hz, or 50/60Hz;

• have a rated voltage of 50V–1kV;

• have a nominal output power ranging of 0.12kW–1MW;

• are designed for continuous operation; and

• are intended for operation on the public power grid.

Lenze has compiled a dossier of information on the Directive and a checklist for OEMs and machine operators. Its Ecodesign Web page includes information such as fact sheets on efficiency requirements for different countries, and FAQs on the Directive.

The company is also launching a Web-based planning and conversion tool to simplify the switch to its new motors and to optimise machines. The tool will take a model number of an existing motor and suggest how it could be replaced to ensure compliance with the Directive.

Lenze claims that, if machines are viewed holistically, drive systems can achieve energy savings of 20–50%. The biggest savings come from choosing drive dimensions and motion profiles that match the process requirements. The use of inverters to adjust the power, or feeding the brake energy into the DC link, offer further possibilities for optimisation.

Lenze’s new motor platform offers the opportunity for standardisation. It says that the ability to use the same motors around the world will allow machine-builders to reduce the number of drive variants they offer, and thus to cut their costs.