- Home » News » Product News

£5,500 delta robot can pay for itself within six months

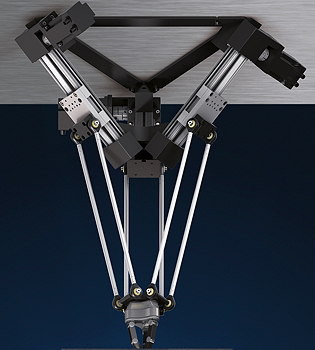

The German engineering plastics specialist igus has combined several of its standard components – including maintenance-free belt drives, encoders, Nema stepper motors and lubrication-free link rods – to create a delta robot that costs less than half as much as some rival systems (which can exceed £20,000 or $26,000) and can pay for itself in around six months.

Igus is supplying the robot either as a kit (costing £5,500/$7,100 without controls) or fully assembled for £6,000 ($7,700). Igus will supply its own D1 controller for an additional £1,000 ($1,300), or customers can opt to use their own controls. There is also a choice between stainless-steel or carbon fibre link rods.

“We estimate that with the usual integration costs, each Delta robot installation will be around £10,000 to £15,000 ($13,000–$19,400), which means that it will pay for itself after a few months,” says igus’ UK managing director, Matthew Aldridge.

The 15kg robot can handle loads of up to 1kg with a precision of ±0.5mm and achieve speeds of 3m/s and accelerations of 60m/s2. It can carry loads of up to 5kg at lower speeds.

Pick rates of at least 60 per minute are possible. Although some other delta robots can pick five times as many items per minute, they cost much more.

“We’re not trying to compete with robots that can do 300 picks/minute,” says Aldridge. “We’re not aiming at the top end.”

He believes that the low price-point of the igus robots will attract those “who want to make a step into automation, but have found it too costly so far”.

As well as the cost advantage, the igus robot should be easier and cheaper to own than some rivals that need to be maintained and well-lubricated. The robot is based on three igus drylin ZLW toothed belt axes that need no lubricant and thus no maintenance.

Aldridge reckons that a robot carrying items weighing around 250g should have a life of about 15 million cycles – or two years in a typical application. When the axes’ liners become worn they can be replaced easily. “You won’t get catastrophic failures,” he predicts.

The robots are aimed at simple assembly, pick-and-place and test and measurement tasks. They can be used with the customer’s own choice of grippers, including pneumatic suction types. Aldridge reports that most of the interest so far in the UK has been from companies in the packaging sector.

Igus has set up a low-cost automation business to handle the robots. Customers who opt for the kit version will receive it within 24 hours of placing an order. Alternatively, igus will assemble them to order in the UK. They will be delivered on a transport frame ready for installation.

Aldrige expects to sell “tens” of the robots in the first year, and hopes that sales will ramp up to “hundreds” in subsequent years.

Initially, the igus robot is available in one size, but Aldridge points out that the linear belt drives on which it based are available in both larger and smaller sizes.