- Home » News » Product News

Factory monitoring platform works with any equipment

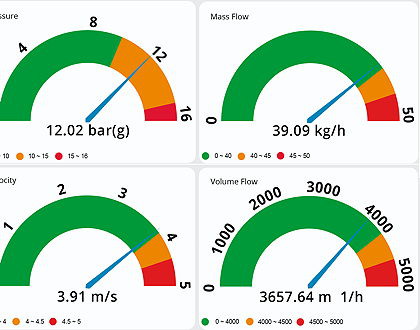

The German sensor-maker Sick has launched a platform that collects data from any factory source – including sensors, machine controllers and IIoT devices from any manufacturer – and displays it in real time, generating alerts and alarms, and visualising historical trends via dashboard graphics. The vendor-agnostic Field Analytics platform will help manufacturing and logistics organisations to optimise their performance by providing application-specific condition monitoring and process insights, independent of the machinery and systems that they use.

Users can aggregate data from various machines and automation systems, or augment legacy automation systems to provide additional insights. The system is scalable, allowing it to be adopted on a project-by-project basis, or at a wider organisational level.

“Operators who want to gain more insights across a production floor, factory or warehouse can feel quite daunted by the prospect of collecting and comparing data from many different machines or applications,” explains Charlie Walker, Sick UK’s digital solutions consultant. “Faced with a sea of information, it can be difficult to isolate the specific factors that are affecting operating efficiency. The data could come from all sorts of sources that use different communications protocols. Information could even still be recorded manually, be stuck in silos, or bogged down in bottlenecks.

“Even if operators already extract some data from their existing automation, they can find themselves locked out of PLCs or other systems,” he adds. “So, they cannot increase the amount of diagnostic data from their legacy systems, even when they replace switched devices with IO-Link sensors, or configure edge integrations using IO-Link Masters.

“Field Analytics can solve these problems easily by collecting data from all of these disparate sources without costly and time-consuming adaptation of existing systems,” Walker continues. “Operators can extract more information about the health of their machines, while interrogating their operating efficiency in new – and sometimes surprising – ways.”

The platform can be used with data extracted from a variety of sources, including sensors, PLCs and smart IIoT edge devices. If necessary, Sick can work with customers to add smart sensors and edge devices to machinery or automated systems as part of a Field Analytics project.

A user management module manages access rights. The data collected can range from the service status of sensors to machine health parameters, such as vibration or temperature.

Operators can set up and trend KPIs (key performance indicators) both historically and in real time. Real-time alerts allow them to react quickly to production or process anomalies that might otherwise lead to machine failures.

The platform can track operational effectiveness. The dashboard can also trend other measurements – such as compressed air usage – or calculate and track production costs – for example, energy consumption.

Field Analytics is compatible with common communications protocols including Rest API, OPC UA and MQTT.

Sick: Twitter LinkedIn Facebook