Low-cost cobot resurfaces after two years of development

In 2015, a London-based start-up called Automata announced that it had developed a six-axis collaborative robot called Eva that it was planning to sell for about £3,000 – thus undercutting most of the competition substantially. Then things went quiet.

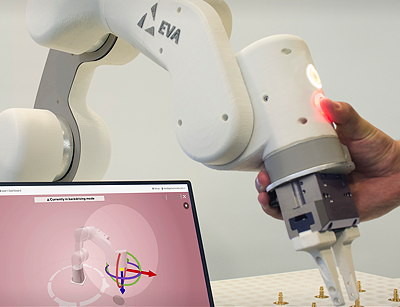

Now, Automata is back with a new-look version of Eva at a slightly higher price – £4,990 ($6,570) – and a larger payload capacity – 1.25kg, compared to the original 750g. The company – founded by former architects, Mostafa Elsayed and Suryansh Chandra – has spent the past two years refining and enhancing the robot, which has been through more than 18 versions and been subject to rigorous lifetime testing. Even at its new price, the robot arm is claimed to be much cheaper than conventional arms of a similar size, which can cost more than £20,000 ($26,360).

The robot has undergone trials with a multinational automotive supplier, a producer of laboratory instruments, and a manufacturer of machined components. Feedback from these users has been “very positive,” according to Automata. “They are particularly impressed by the ease-of-use and low weight, easily allowing to configure Eva for different tasks,” it reports.

Automata is now taking reservations for the robot and is hoping to start shipping it in mid-2018. It expects Eva to be used for tasks such as machine-tending, product-testing, spray-painting and simple pick-and-place operations. The low cost will make the robot economical for low-volume tasks.

The company believes that Eva will fill a gap in the market. “This is truly a game-changer for both robotics and the small manufacturer,” says Elsayed. “Eva is a high-quality, high-spec robot that doesn’t require a technical expert to program it and doesn’t cost the earth. Best of all, it will help growing businesses to save money in the long run.”

“Current industrial robots are designed for heavy industry tasks that require extreme power and precision,” adds Chandra. “But people don’t work like that, and 90% of automatable tasks in manufacturing such as machine-tending are still done by people on a daily basis. We designed Eva to make automation simple, quick and affordable, so people can leave the menial work to Eva and focus on more intelligent tasks.”

Eva has a similar reach to a human arm, and offers a repeatability of up to ±0.5mm. It weighs 8kg, including a controller which is integrated into its base, making it easy for one person to set it up or to assign it to a new task. Similar-sized robots weigh more than 40kg with their controllers, according to Automata.

Automata has developed, from scratch, a software package called Choreograph to accompany Eva. It provides services such as remote diagnostics and predictive maintenance. While basic robotic tasks can be programmed by guiding the arm using one hand, the software offers more detailed control and can be accessed remotely via a Web browser.

Because Automata could not find a suitable low-backlash gearing system that was affordable and reliable, it developed its own. It claims that the last major breakthrough in commercially usable robotic gearing happened in 1957!

Since its original announcement, Automata has had more than 5,000 enquiries, only 39% of which have involved traditional manufacturing applications. The others have included 19% for r&d uses, 12% for “creative’ applications, and 6% from integrators and resellers. Automata estimates that by focussing on six sectors – metals, pharmaceuticals, electronics testing, automotive, rubber manufacturing and food and beverage – in four markets (the UK, Europe, the US and Canada) it could target a market worth £26bn.

As well as selling its robot in the conventional way, Automata also plans to offer the arm on a “robotics as a service” basis, for which users will be charged a monthly fee. For £490 ($645) per month, they will qualify for a free upgrades to their machines when these become available, and a pledge from Automata that any downtime will not exceed 48 hours. For £690 ($900) per month, their package would include predictive maintenance and a “zero downtime” warranty.

Automata says its goal is to bring the next revolution to manufacturing through simple, affordable automation. Its team is made up of engineers, software developers and roboticists, and the company has backing from ABB, and from the venture capital firms LocalGlobe and Entrepreneur First.