- Home » News » Technology News

Automated lubrication could extend guide lives

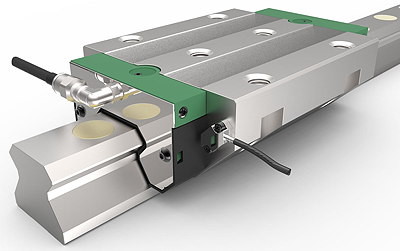

Schaeffler has demonstrated a system which determines when linear recirculating roller bearing and guideway assemblies need lubrication, and relubricates them automatically, thus extending their lives and minimising the risk of failure.

The system consists of a carriage that runs on profiled guide rails and is equipped with special built-in sensors, an electronic evaluation system, and an automatic lubricator, such as Schaeffler’s FAG Concept8. Up to six carriages can be monitored on one axis.

According to Schaeffler, the system offers the following attractions to machine-builders and operators:

• maintaining optimum lubrication conditions will extend the operating lives of linear guidance systems and help to achieve high levels of manufacturing quality;

• for guidance systems with small loads, the amount of lubricant needed could be cut by up to 30%;

• if the inside of the carriage becomes contaminated, a “flushing” effect will prevent damage to the guidance system; and

• as a consequence, machine downtime will be reduced and availability increased.

Defective rolling bearings and linear guidance systems are one of the most frequent causes of machine downtime. Insufficient lubrication or contamination – and, in some cases, mounting errors – are often responsible for guidance systems failing before the end of their expected operating lives. Relubricating guidance systems based on their needs can reduce unplanned downtime dramatically, boosting machine availability.

As lubricants age or are lost, they lose their damping effect in the rolling contact. The new system exploits this relationship. As the lubricant film in the rolling contact gets thinner, the rolling elements transfer more vibration energy to the saddle plate. The system generates a threshold value based on the bearing’s condition. When this value is exceeded, it triggers an impulse to activate the lubricator.

If an axis is travelling short distances and is subject to low machining forces, these impulses are less frequent. If load conditions become more severe, they become more frequent. If foreign bodies enter a carriage as a result of contamination, or the carriage becomes contaminated with cooling lubricant, this is detected immediately via solid-borne soundwaves, and a lubricating impulse is triggered.

As long as these soundwaves stay above a threshold value, the lubricating impulses are repeated. As a result, the contamination is flushed out of the carriage, along with the lubricant. If the key values return to normal, the raceways and rolling elements will escape damage from the contamination.

Without this innovation, the guidance system would continue to operate with contamination in the rolling contact until the next planned lubrication – and would thus be damaged, probably resulting in premature failure.

A major challenge in developing the new system was how to build sensors into the limited space in a linear guidance system. A sensor had to be developed specifically to record the lubrication conditions in the carriages and to fit in the restricted space.

The new technology, which was demonstrated at the recent EMO machine tool exhibition in Germany, is the second generation of a system that was presented as a concept at EMO 2015. The new generation is currently in pilot production.

As well as extending the operating lives of linear guidance systems, the lubrication-monitoring technology will also provide a basis for other applications. For instance, analysing the relubrication intervals could be used to predict the remaining useful life of the linear guidance systems. This will make planned and requirement-based maintenance possible, reducing unplanned downtime further, and maximising machine availability.