The real obstacles on the road to smarter factories

Many manufacturers are not enjoying the full benefits of digitalisation, partly because of the difficulty obtaining real-time data from their plants and machines. In this guest column, Jan Hemper, technical director of Gambica* member, InControl Systems, argues that such barriers can be overcome by closer cooperation between SIs and suppliers.

My biggest challenge is connectivity,” said a manufacturing solutions architect who works for a household name in the food and beverage sector. This sentiment is echoed by many manufacturers, who are desperate to enjoy the benefits of the latest software tools for improving productivity, maintenance and their processes. In short, the managers want the attractions that these tools offer, but connected to the real-time sensor data from their machines and processes.

For example, there are plenty of companies that sell maintenance planning software that runs on smart tablets, but still relies on manual data input, rather than obtaining real plant data directly from the sensors on the machines.

The 2017 UK Made Smarter Review listed 31 obstacles to adopting industrial digitalisation. At positions 3 and 6 were “lack of certainty to the solution working” and “legacy infrastructure”. At number 2 was “lack of skills to design new systems and implement”.

My experience from manufacturing sites supports these views. While number 2 is solved by finding the right partners to work with (barrier number 4), the challenge of connecting to legacy controls and machinery needs to be overcome to provide confidence that the solution will work.

In my view, “Made Smarter” is a more relevant term than “Industry 4.0”, which often frightens business leaders away from adopting digital systems that converge OT (operational technology) with IT (information technology). We prefer to start with the business need, rather than the technology available. If the business need is to reduce waste, then you can improve the process before waste is created. Or to understand when and why a bearing is about to fail, so that it can be replaced and a root cause can be understood. Then we can use technology to collect that data in real-time and present it to the people who need it.

Too often, business managers take siloed approaches to their needs: planned maintenance management is one project; OEE (overall equipment effectiveness) is another; statistical process control is yet another; as is shop floor visual management.

Yet to make these capable and AI-enriched systems perform at their best, they all need access to the same equipment. So why treat them separately?

How many factories have you seen with challenges such as this? Managers and business leaders need more data at their fingertips to know where best to allocate resources to drive down waste and energy, to increase uptime, and to boost productivity and profits.

But their factories are full of legacy equipment, machines and control panels that may have been in use for a quarter of a century or longer. And even today, some machinery suppliers struggle to offer them connectivity into standardised open-architecture systems that would allow all of their machines and all equipment to be connected on a single network where all of the data can be made available to all software applications. Without this, the roll-out of Made Smarter to SMEs will be piecemeal, fragmented and not able to demonstrate an attractive ROI.

But it is possible to achieve this, with planning and forethought, standardising on vendor-agnostic methodologies, and working with vendors and integrators who are prepared to connect to each other for the benefit of the end-user.

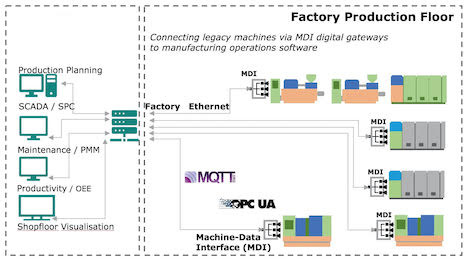

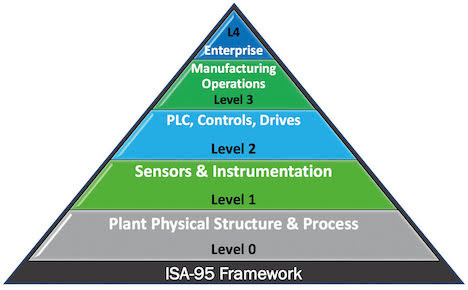

The connectivity of plant data from Level 1 of the ISA-95 model (Fig 1), through controls equipment to Level 3 and 4, is possible by adopting the correct architecture, and using open protocols such as OPC-UA and MQTT. Data can be routed, if not directly from the machine, then through machine data interfaces (MDIs) that act as digital gateways from the machine to the factory Ethernet network, where a digital backbone can be created from which all applications can share data. A common MDI design can therefore be used to facilitate a standardised methodology to solve the real challenges that face manufacturers on their journey to smart factories.

Systems integrators working with hardware and software vendors, and especially machine-builders, need to cooperate openly using these connectivity standards to ensure that manufacturers can invest with confidence, knowing that they are heading down a path with measurable returns.