- Home » News » World News

Group aims to link location-tracking technologies

UPDATED: A global group of 60 industrial companies, led by the machine-tool maker Trumpf, and including Siemens, Sick and Pepperl+Fuchs as members, is drawing up a new positioning technology standard for tracking items including AGVs and drones. The consortium, called Omlox, had planned to unveil the technology at the 2020 Hannover Fair but, following the event’s cancellation, it is holding an online launch from 29 June to 2 July instead.

The consortium has also handed the project over to the Profibus user organisation, which will promote the standard globally. “As an independent organisation, we can continue to make sure that all partners will be able to contribute on an equal footing,” says Profibus CEO Karsten Schneider.

Interfaces to connect products have already been defined for omlox. “Like USB, which has become indispensable in the office, we are now enabling different positioning solutions to communicate for the entire industry worldwide,” Schneider adds. An Omlox logo on products will guarantee that they connect comply with the standard.

Every manufacturing site contains many moving objects, such as materials, tools, people and transport systems. Omlox’s aim is to create a standards-based digital representation of these items at a reasonable cost that will allow interoperability and will help to secure future investments.

The standard will link tracking technologies such as RFID, 5G, GPS, BLE (Bluetooth Low-Energy) and UWB (ultra-wideband), to determine the location of objects with accuracies measured in centimetres.

To date, it has not been possible to connect location technologies from different suppliers. The new standard aims to change that, making it possible to connect and combine devices from different vendors in a similar way to USB and Bluetooth in consumer applications.

“The goal of the initiative is to make it easier for industrial customers to use hardware and software from different vendors. This saves the end-customer time and money,” explains Thomas Schneider, managing director of research and development at Trumpf.

All positioning data, no matter how it is obtained, will be displayed in a uniform coordinate system, making it easy to integrate technologies from multiple vendors. It will no longer matter which supplier provided a site’s infrastructure.

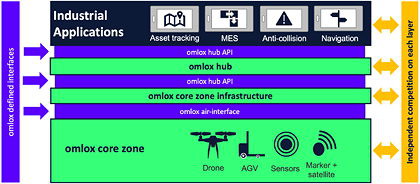

Omlox plans to build a bridge between hardware manufacturers and infrastructure providers on the one hand, and suppliers of applications such as navigation and asset-tracking on the other. To make this a practical reality, the location engines, data hubs and applications will need open interfaces. Data from different localisation systems will be merged and handled in a multi-layer architecture.

Any location service needs four elements:

• An identifier Moveable objects need to be identified which, for unique objects, can be done using image recognition. But because different objects can look similar, an unambiguous identifier is needed.

• An infrastructure Information on the moveable object has to be transported, and a location reference needs to be attached. This can done in various ways, including RFID gates, BLE or UWB beacons or landmarks, and Wi-Fi networks for Slam-based AGVs.

• XYZ “geo-referencing” Location-aware objects have their own coordinate systems. But they have to interact with other location-aware objects, so there can only be one definition of the coordinates in a smart factory. Talking the same language is essential.

• Applications These are needed for navigating, tracking, routing, analysing, warning and so on.

Omlox is drawing up standards that will define three interfaces:

• an air interface between identifiers and infrastructures to provide a physical reference;

• an API between infrastructures and geo-references; and

• an API between geo-references and applications, which can be added to any application.

The APIs will be tested and certified before being made available to network operators.

Users will be able to customise their location systems in a vendor-independent way. Any omlox device from any vendor can be located by any omlox infrastructure. And any omlox hub from any vendor could include omlox core zones or complementary location zones from any other vendor. Finally, any location application that meets the omlox specification can be connected to any omlox hub.

There will be competition at the tag and hub levels. Users will be able to switch between vendors for these elements. Wahls argues that this competition will lead to differentiation. Ultimately, there will be low-cost, high-volume tags, or specific tags for dedicated uses.

It will be possible to integrate the new infrastructure elements with existing technologies such as fire alarms or lighting systems. Omlox predicts that installation costs will drop dramatically. And applications could be re-used, cutting costs further.

Once the omlox standard is adopted widely, the consortium believes, even devices with low additional value for location services will use of it because it will be affordable and familiar. New services will proliferate, such as transparent multi-tier supply chains.

Omlox points out that during the Covid-19 pandemic, many companies have been experiencing problems with supply shortages. The lack of transparency on the status of their supplies has made it difficult, even for large OEM manufacturers, to restart production after the shutdown.

Omlox argues that its system will result in seamless supply-chain tracking. By attaching omlox tags to carriers, and using cloud location services based on cascaded omlox hubs, supply-chain managers will be kept informed about the status of their supplies, both indoors and outdoors, in real time.

For outdoor tracking, GPS will be used, while indoors, omlox technologies will be used. In zones where precise localisation of assets is required, UWB could be used; if room-accurate positioning is sufficient, lower-cost Bluetooth Low-Energy might be more suitable.

The transparency will allow users to adapt to changing environments and new situations. By-products of the supply-chain could also be tracked, improving recycling and increasing efficiency.

Any manufacturing site could implement omlox, adding the new infrastructure to existing location technologies. Extra hardware and applications could be added later if required.

Wahls predicts that as omlox becomes more widely adopted, it will disrupt a variety of industries and replace some expensive technologies in use today. For example, omlox tags could be embedded in employee badges to replace existing building access and attendance-monitoring technologies.

And facilities-management tasks, such as equipment and building inspections, and cleaning and security, could be automated or done autonomously.