- Home » News » World News

Robots help to make drive-through virus testing safer

In a matter of weeks, automation and robotics experts around the world have come up with inventive ways to use their technologies to help tackle the coronavirus epidemic, taking advantage of the fact that automation equipment is not affected by the virus and is ideal for doing repetitive tasks.

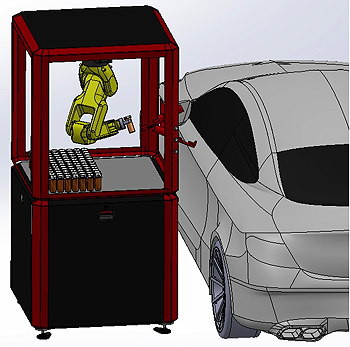

For example, a Bavarian automation specialist, Boka Automatisierung, has designed an automated drive-through station for coronavirus testing. Drivers identify themselves through a car window using a tablet, and a robotic arm hands them a test tube. A video shows them how to collect a sample and, once they have done this, the arm retrieves the test tube. The patients are informed later whether they have the virus or not.

At the Aalborg University Hospital in Denmark, two Kuka robots are sorting more than up to 3,000 blood samples for testing every day, allowing hospital staff to concentrate on more complex activities instead of having to spend hours performing routine tasks.

Automation technologies are also being harnessed to mass-produce the vital protective equipment needed by hospital staff and others.

For example, the German machine-builder, PIA Automation, usually manufactures automated production systems for the automotive and consumer goods industries. Within weeks of the outbreak, PIA had revamped two production lines in China for automated production of up to 140,000 protective masks per day.

With the know-how from this pilot project, PIA is now working on new lines in Germany that will be able to produce more than 1 million respiratory face masks per day.

Another German company, the mechanical engineer Ruhlamat, has also developed a line for producing disposable surgical masks. The masks’ filter materials can be processed flexibly depending on the level of safety required.

A Danish company called Life Science Robotics (LSR) has repurposed a robotic system originally developed for use by physiotherapists, to help medical staff to keep their distance when moving coronavirus patients. The robot, called Robert, is based on a lightweight LBR robot from Kuka.

In care homes, personal robots are helping residents to stay in touch with family members during visiting bans. A robot called James visits people in quarantined rooms, linking them to their families via video connections. A German company RobShare is providing the robots at almost no cost. "We don't earn a cent from this campaign, we just have to make sure that our basic costs are largely covered", says Konstantin Dick from RobShare’s owner, the Hahn Group. “We have already started to look for sponsors so that the campaign can be offered completely free-of-charge for the care homes.”

These examples have been compiled by the German robotics and automation trade body, VDMA. “The flexibility and creativity of the companies has overwhelmed us,” says VDMA managing director, Patrick Schwarzkopf. “Initiatives and new ideas are coming from all sides to use automation technology to overcome the corona crisis. The companies are working at breath-taking speed. A can-do spirit is in the air.”