- Home » News » Technology News

Automated print inspection system avoids nuisance stops

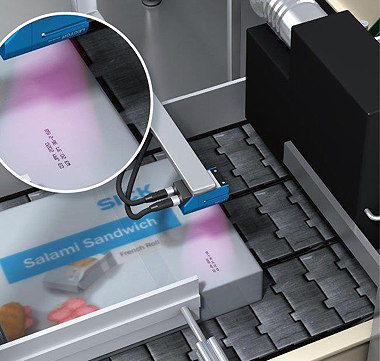

A UK coding and print inspection specialist AutoCoding Systems has collaborated with the sensor-maker Sick to develop what they claim is the first fully-automatic smart vision inspection system for printed coding and markings on food, pharmaceutical and other consumer goods packaging.

The jointly-developed 4Sight automatic print inspection system performs “error-proof” high-speed inspection of printed codes such as dates, and batch and line numbers. Printed messages can be communicated directly from any make of printer using inkjet, laser or thermal transfer technologies, eliminating the costly “nuisance stops” and time-consuming set-ups that conventional vision systems need for them to be taught thousands of images and fonts, as well as the context of the surrounding packaging design, which can affect the inspection.

The application combines AutoCoding’s 4Sight software with Sick’s Inspector P smart vision camera. It is one of the first to be developed using Sick’s AppSpace software platform, which runs apps on board the camera.

The technology allowed AutoCoding “to think about print inspection systems in a completely new way,” explains the company's managing director, Mike Hughes. “The result is a directly networked connection between the printer and the smart camera, coupled with the 4Sight software’s unique ability to self-optimise the code inspection process.

“As the artificial intelligence is already pre-trained in the application, the AutoCoding system knows exactly the printed message it is looking for,” he adds. “So, the system adjusts automatically when the printer changes to a new job. There’s also much more opportunity to finesse the vision inspection criteria and avoid unnecessary line stops, because there can be no false reads as a result of the packaging background, or due to natural variation in the location of the printed code.”

The software checks in one operation that the printed code is correct, present and legible. Because the application is running onboard the high-resolution camera, there is no need for a lineside PC.

Users can define what they class as a good, bad or no-read for each product. There’s no need to teach fonts, configure features or regions of interest on the packaging, or to fixture against an edge or logo.

The system can process inspection images with short cycle times and be used in high-speed applications such as bottling and canning lines. It can be configured to connect with devices such as encoders, and with other systems – to control a rejection operation, for example.

The 4Sight system can provide diagnostic reports and event logging, and will store and forward inspected images to a chosen network location.

“All too often we are called in to help production teams who have ended up disabling their vision systems altogether because of the nuisance caused by frequent, unnecessary line stops as a result of an overly-sensitive system,” says Neil Sandhu, Sick’s UK product manager for imaging, measurement, ranging and systems. “The problem is too complex for the operators to fix, so the vision system simply becomes a white elephant. As a result, the manufacturer remains at risk of receiving penalties and damaging their customer relationships if code inspections on delivery result in products being returned.

“That’s why the 4Sight system is such an important breakthrough – because it offers a high-performance, dependable solution that’s easy to set up and use.”