- Home » News » Technology News

‘Revolutionary’ plastic gearbox ‘will out-perform metal boxes’

Genesis Robotics claims to have developed the world’s first plastic gearbox that can outperform metal gearboxes. The backlash-free box – which it calls the Reflex torque amplifier – has four times more engaged teeth than a conventional planetary gearbox, allowing it to achieve a similar torque-to-weight ratio. And because its parts can be injection-moulded, it should be easier and cheaper to manufacture.

According to the Canadian company’s chief technology officer, James Klassen, the “challenge” of conventional planetary gearboxes is that their carriers and bearings add weight, inertia and costs.

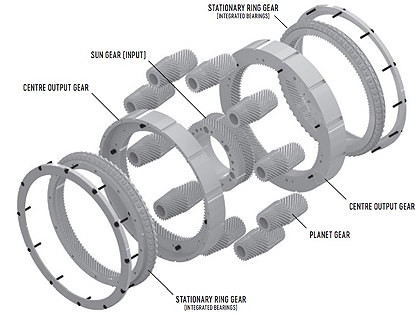

The secret to the “revolutionary” performance of the Reflex, he explains, is a pair of stationary ring gears (with integrated bearings) on either side of the disc-shaped gearbox. The box directs a symmetrical force transfer from these gears to a central output ring gear. All of the forces are balanced and the symmetrical construction prevents torsional deflection of the planet gears, as well as eliminating the need for a planet carrier and for planet-gear bearings.

By eliminating the bearings, the planetary gears can be hollow, reducing weight and introducing a slight compressibility in the radial direction. This provides stiff enough torque transfer through the axial direction, while introducing the slight radial flexibility. This allows the gears to be preloaded, which, combined with the use of tapered teeth, eliminates backlash.

The slight flexing of the planets in the radial direction also compensates for any expansion caused by heat, allowing them to operate smoothly at any temperature.

“The unique construction of the gearbox allows four times as many teeth to be engaged compared to a typical metal gearbox,” says Klassen. “Plastic is a quarter of the strength of steel so, with four times the number of teeth, we end up with same torque-to-weight but at a much lower cost.”

He describes the new design as “the culmination of 35 years of development”.

The torque amplifier offers scalable torque, size, and gear ratios, making it adaptable to a variety of applications. But Genesis’ main interest is in its potential ability to help deliver low-cost, high-performance robots.

The back-drivable box can be combined with the company’s existing Livedrive motor – which, it claims, has three times the torque-to-weight of any other motor – to create safe, low-cost robot arms made of injection-moulded plastics, with fewer parts, that will match – or even improve on – the performance of conventional metal-based robot arms.

“The centreline output eliminates scissor points on the robot and makes it more like a human arm,” Klassen points out. “This creates a much safer, smoother and less expensive robot, because it’s a much simpler construction.”

Initially, Genesis plans to offer a 160mm-diameter, 53.5mm-wide version of the torque amplifier, weighing 760 grammes, and with a rated torque of 44Nm, a peak torque of 87Nm, and a gear ratio of around 30:1. The scalable technology could deliver ratios from 4:1 to 400:1.