- Home » News » Product News

Planar gantry is 30% faster than Cartesian handling systems

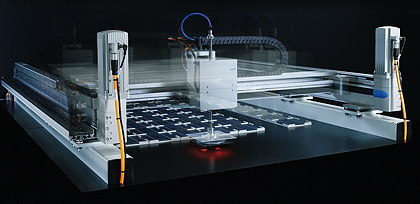

Festo has developed a dynamic gantry system that, it claims, is 30% faster than conventional Cartesian handling systems, with initial costs that are comparable. The EXCH planar surface gantry is aimed at high-speed assembly operations where small, light mass-produced items need to be positioned quickly and flexibly.

The gantry has a rectangular working area similar to that of two Scara robots, and larger than that of a delta kinematic robot. Festo points out that delta robots can only operate in circular areas, while Scara robots handle only kidney-shaped ones. It suggests that this makes the planar surface gantry more economical both in terms of its mass – around 150kg – and space requirements.

The gantry has a low centre of gravity and a simpler frame than high-speed parallel kinematic systems. It operates at speeds of up to 5m/s and acceleration rates of up to 50m/s², and can perform 100 picks per minute. It can place objects weighing up to 4kg to an accuracy of 0.1mm during suction pick-up and gripping operations.

The gantry is driven by two static servomotors via a single recirculating toothed belt. The motors do not move in the X/Y plane, allowing fast, dynamic movements with low wear.

The gantry can be ordered using one part number and comes with a ready-to-install control package including an axis controller, 3D motion controller and safety functions.