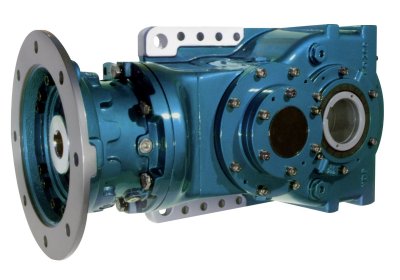

The Italian gear manufacturer Brevini has come up with a gearbox that combines the high efficiency, low weight, and high reduction ratios of planetary gear stages, with the high capacity, strength and durability of bevel helical gears. The resulting Posiplan PH in-line and BPH right-angle hybrid boxes are said to be powerful, yet light and efficient. They are aimed at medium-to-large industrial applications needing low-to-medium speeds and high torque.

The boxes use a compact, high-speed planetary stage at the input end and a slower, high-torque helical stage at the output side. This design is claimed to offer the best of both worlds and to deliver far higher capacities from smaller boxes, allowing a reduction in size, or a significant increase in capacity over traditional designs. The high power-to-weight properties of the planetary gears provide OEM designers with a lighter, smaller alternative to helical and helical/bevel boxes.

The boxes offer nominal torque capacities up to 27kNm – soon to be extended to 67kNm.

"In the past, some engineers have been reluctant to design a planetary shaft-mounted gearbox into the machine because the driven shaft does not engage all the way through the gearbox," explains Jon Snaith, Brevini’s general manager for sales in the UK. "The Posiplan, by contrast, has a helical final-stage reduction, thus removing this objection."

As well as delivering improved performance, the gearboxes – available in ten motor-harmonised sizes – are also said to help boost motor efficiency and motor life by providing the most efficient input speeds for common motors.

The shaft-mounted gearboxes can be mounted in any orientation and can replace fast-wearing and high-maintenance transmission alternatives such as belts, chains and pulleys. Costs can also be reduced compared to worm/wheel transmissions because of the boxes’ low weight and higher efficiency, which allows smaller drive motors to be used.

The in-line PH series offers ratios from 12:1 to 2000:1 in the one casing without needing to plug in additional helical gearboxes. The boxes are ideal for space- and weight-restricted conveyor or mixer applications requiring high levels of torque. Torque outputs range from 5.8–67kNm via single-, double- or triple-stage planetary inputs and a single-stage helical output for shaft diameters from 70–140mm.

The right-angle BPH boxes provide reduction ratios of 30:1 up to 1000:1 as standard and are aimed at applications requiring 90-degree operation, such as cranes, crushers, extractors or continuous extruding assemblies.

The gearboxes use high-speed bearings on the input shaft, taper roller bearings in the internal gearing to resist high thrust loads and over-sized bearings on the output shaft to maximise rigidity. Nitrile labyrinth seals protect against lubricant leakage and contamination, further prolonging the boxes’ wear life.