- Home » News » Technology News

Drives perform condition monitoring without sensors

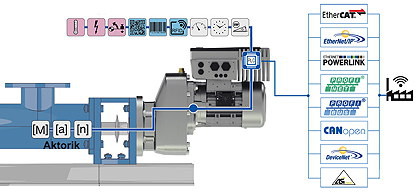

At the recent SPS IPC Drives show in Germany, at least two drives manufacturers – Nord Drivesystems and Danfoss – were demonstrating VSDs (variable-speed drives) that can perform condition-monitoring functions without needing the usual sensors.

Nord’s system, which it plans to incorporate into all of its frequency inverters with built-in PLCs from late 2018, provides predictive maintenance using “virtual sensors”. One potential application is to estimate the remaining life of the lubricating oil in an attached motor and to use this to calculate maintenance dates – without needing sensors.

The drive’s onboard PLC evaluates data on the motor’s current, voltage, and speed, and from this it infers the current oil temperature. This estimate is combined with product-specific characteristics of the lubricant to determine its ageing, allowing use of the lubricant to be optimised.

Nord says it has validated that the calculated oil temperatures correlate closely with real measured temperatures. The company is currently checking temperature curves under varying load conditions. It says that calculating maintenance intervals in this way will help to cut operating costs and to increase plant availability. It will also eliminate the hardware costs for sensors and their controls.

Danfoss describes its embedded maintenance system as a “breakthrough technology”, with the drive acting as a smart sensor that can monitor stator insulation, vibration and loads.

To monitor the stator insulation, the drive detects a single turn-to-turn fault before the insulation fails. The motor can continue to operate because this occurs at an early stage in the development of a fault, and the drive gives a warning signal.

To monitor vibration problems, the drive works with an external vibration sensor and can correlate the speed of the motor with the measured vibration levels – which is not always possible when using an external vibration monitor by itself. The drive can use this information to determine imbalances in the motor and to give a warning if it spots potential problems.

The third possible application is to monitor the motor load to detect problems such as sand in pumps or clogged filters in fan systems.

If required, the maintenance data generated by the drive can also be sent to the cloud, where advanced analyses can be performed.