- Home » News » World News

Toyota and Hitachi to install IoT platform at automotive plants

Toyota Motor Corporation and Hitachi are collaborating to build an efficient production model based on Hitachi’s Lumada IoT (Internet of Things) platform, which incorporates technologies such as AI (artificial intelligence) and big data analysis.

The companies plan to verify the platform at Toyota plants in Japan and to use it to identify and solve issues at the sites with the aim of accelerating PDCA (plan-do-check-act) cycles, and improving quality and productivity.

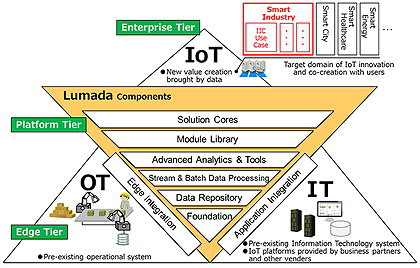

The Lumada platform, announced by Hitachi in 2016, collects and exploits data. Facilities, devices, and other systems at the Toyota plants will be connected to the platform which will consolidate and analyse their data. The partners plan to analyse not only data in single processes, but also data that extends across multiple processes, and to use this to visualise complete plants and improve their efficiencies.

Toyota and Hitachi want to establish a system that prevents unexpected facility failures by analysing data and to extend this system to other processes to improve maintenance operations. They also want to acquire and analyse product data that spreads across multiple processes to improve quality. The two companies aim to establish an efficient production model with an accelerated PDCA cycle, and to verify processes aimed at improving quality and productivity.

Since announcing the Lumada platform last year, Hitachi has applied the technology at its own sites and those of some customers.

For example, it is working with the machine-tool builder Okuma to create an advanced, efficient production model that supports mass customisation. The aim is to double productivity and to halve lead times.

Hitachi has also been working with the chemicals giant Daicel to create an image analysis system designed to improve product quality and productivity by detecting signs of failures and deviations in employee actions. The system is said to have helped Daicel to improve its in-process guarantee rate for products.

Based on these initial applications, Hitachi has released a second version of Lumada which can run either locally or on the cloud, and supports IoT deployments either in the core or at the edge.

The software also supports “asset avatars” – Hitachi’s version of “digital twins” – which provide digital representations of assets and analytics metadata, and serve as digital proxies for business and industrial assets. Using continuously updated sensor values, the avatars provide insights into the health and performance of the assets, and help to eliminate “blind spots” by improving access to machine, business and human data. Hitachi says that these capabilities can help users “to move more rapidly from measurement, to management, to improvement”.