- Home » News » Technology News

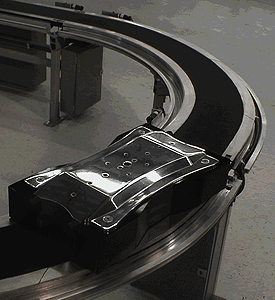

Algorithms target linear motor track systems

The Israeli motion control specialist ACS has developed a series of algorithms specifically to control closed-track transportation systems driven by linear motors. It says that such systems offer better performance than track systems based on moving magnets, at a fraction of the cost.

ACS says that its development will provide off-the-shelf controls for producers and users of linear-motor-based track systems, as well as offering an alternative to users of the costly, limited-performance moving-magnet systems.

“Moving-magnet motion solutions typically require complex commutation control, multiplexing between sensors, and several (non-standard) drives, one for each section of track – meaning the number of drives required increases with the length of track,” explains Boaz Kramer, ACS’ director of control and support.

“Moving magnet solutions also have limited performance, as they usually implement a six-step trapezoidal commutation and Hall-sensor-based feedback, which have limited resolution and accuracy,” he adds. “Plus, with limited force constants, moving-magnet solutions are not suitable for applications such as high-performance printing machines.”

The new algorithms, which run on ACS’ SPiiPlusNT motion controls and drives, compensate adaptively for changes in commutation periods and motor force constants that result from the curved magnets in arc-shaped linear motor tracks. They also provide seamless transitions between feedback devices during motion, allowing high-resolution optical encoders to be used on parts of the track.

The control scheme treats each forcer on the track as a linear motor axis, and uses sinusoidal commutation to provide smooth motion. The algorithms can compensate for cogging. Position errors during motion are said to be a few microns or less.

Each moving forcer needs one drive, no matter how long the track. The motor force constants are up to 1.9kN continuous.

The algorithms have already been applied to applications such as high-throughput digital printing, packaging and additive (3D) printing.