- Home » News » Technology News

Programmable light tower ‘will revolutionise the market’

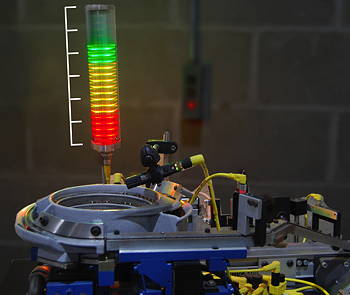

Balluff believes that it will revolutionise the light tower market with the first system that can be adapted freely to almost any requirement without complex hardware reconfiguration. The software-configurable Smart Light, which can include up to 20 360-degree LEDs arranged vertically, can do much more than simply signal predefined operating states using three colours.

The light, which costs less than most HMIs, can be used to show trends in physical values, fill levels, temperatures, or even the position of a carriage detected by a position sensor. The usual costly combination of coloured modules is no longer needed because the device adapts to the new tasks on-the fly. Balluff points out that even light towers that are set using DIP switches cannot be changed while they are running.

The Smart Light can be connected to almost any industrial network via the open IO-Link system, using simple unshielded, three-wire cables. It can be used with modular, IP67-protected I/O-Link products from a variety of vendors, eliminating the need to have a remote I/O box simply to control an indicator light.

The light tower, which is controlled using simple bitmaps for the outputs, can operate in three modes:

• Stack light mode This allows you to program up to 20 rows of LEDs in up to five positions, and to choose from five standard colours or to configure new colours. You can switch between solid, flashing, and blinking displays.

• Level mode This allows you to associate a “bar meter” scale with an analogue value and to program high or low level signals, freely configuring the colours, zones, and levels. It can be used to indicate variables such as machine speed, throughput, output quality, operator performance, container levels, or pick-to-light signals.

• Run mode This indicates machine status using a simple scrolling light and can be used to signal a problem or action required. You can set the colour of the scrolling light, background and speed.

The photo above shows the Smart Light system being used to indicate the fill level in a feeder hopper.

One part number covers all applications, avoiding the need to keep a variety of spare parts and bulbs. The Smart Light uses a standard M12 connector and is IP54-protected, so it can be mounted quickly and easily on a machine without needing a remote I/O box or multiple terminations in a controller.