- Home » News » Technology News

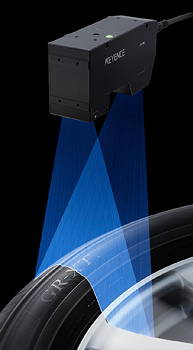

Profile scanner is ‘30 times faster than its rivals’

Keyence claims to have made a breakthrough in profile measuring technologies with a system that it says is about 30 times faster than its closest rival. The LJ-V system can measure 12.8 million points (or 64,000 profiles) in a second, and can scan targets moving at speeds of up to 6.4m/s in 0.1mm steps.

The system can also generate a 3D profile instantly from the 2D profiles, as well as performing 16 measurements simultaneously on the same profile. Specialised programming is unnecessary, and an automatic position adjustment function manages differences in position of the parts being measured. Operators can check results instantaneously during adjustment or measurement.

The system allows 3D measurements to be made easily at the end of production lines, avoiding the need for manual checks. It can also be used to analyse production drifts in real time.

Key to the technology is a fast new CMOS sensor with a high sensitivity and a dynamic range that is claimed to be 64 times better than the best 2D systems. The device can measure dark and shiny surfaces with a high level of stability. It is coupled to a processor with an ultra-high-speed pipeline.

The system combines a blue laser (which is characterised by a narrow beam because of its short wavelength) with a 2D lens that focuses the laser into a thin, intense beam. The blue laser also provides stable detection of targets at high temperatures because the diffusion on the surface is less than for a red laser.

The system’s precision is ±7.6µm and its repeatability is 0.4µm. The linearity is 0.1% of full scale. It can measure parts of all sizes and has an operating range of up to 300mm for 240mm profiles.

The profile measuring system uses a double light source and a “unique” technique, known as known as double polarisation, to identify multiple reflections that could disrupt measurements. This is critical for measuring metals with complex profiles and surfaces.

Implementation is said to be simple with 74 easy-to-configure measurement functions which cover most potential applications. The IP67-protected system can be used with a dedicated touchscreen or an off-the-shelf monitor.