At the Frankfurt Motor Show in September, the Schaeffler Group plans to showcase a battery-powered four-wheel-drive vehicle with active electric differentials on both axes. These components combine an electric drive with the option of wheel-selectable drive power control, allowing torque to be distributed between the wheels to enhance driving dynamics, safety and comfort.

“The eDifferential enables active intervention in driving dynamics via well-directed power supply – rather than braking intervention and therefore power reduction, as is the case with ESP (Electronic Stability Programme),” explains Prof Dr-Ing Peter Gutzmer, Schaeffler’s president of technical development.

“The active electric differential significantly improves power transmission when driving on surfaces with different friction coefficients,” he adds.

“Furthermore, it assists steering and has a clearly positive effect on driving dynamics, safety and comfort,” Gutzmer continues. “In addition, the use of two eDifferentials enables the longitudinal distribution of drive torques [between the front and back wheels].”

By controlling the flow of forces to the four wheels, actively controlled torque distribution – known as torque vectoring – allows a vehicle to be controlled almost without needing to use its steering and braking. The potential fields of application range from sports cars with high driving dynamics, to conventional passenger cars and agricultural vehicles.

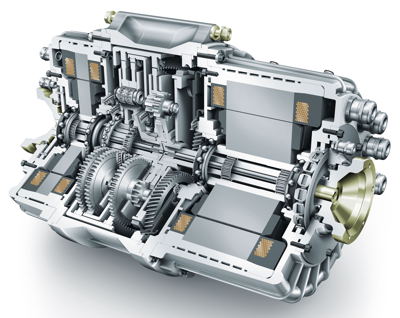

The system (above) integrates two water-cooled permanent magnet synchronous motors of differing sizes, a planetary gear, a gearbox for active torque distribution, and a lightweight differential. The motors were developed by Schaeffler’s Idam (INA Drives & Mechatronics) division.

The primary motor delivers up to 105kW and 170Nm, while the smaller one controls torque distribution and only needs to deliver 5kW to generate up to 2,000Nm of torque difference to the axle.

The use of two active electric differentials results in an combined output of up to 210kW for the four-wheel drive system. Lithium-ion batteries with an 18kWh capacity provide energy storage on board the vehicle and are fitted in the cardan shaft tunnel, in front of the rear axle.

The 1,900kg test vehicle (above), known as the ActiveDrive, is based on a Skoda Octavia Scout. It can accelerate from 0 to 100km/h in 8.5 seconds, has an electronically regulated top speed of 150km/h, and a cruising range of up to 100km in the present configuration.

Novel features of the vehicle include: an integrated electromechanical parking lock; a forced-lubrication system for the gearbox that needs no oil pump; sheet-metal planetary carriers; and various high-speed, friction-optimised bearings. The vehicle’s electronic controls have been supplied by AFT (Atlas Fahrzeugtechnik), Schaeffler’s automotive drive train mechatronics and vehicle testing division.

The ActiveDrive complements two other Schaeffler concept vehicles: the CO2ncept-10%, based on a Porsche Cayenne, which demonstrates the improvements that are possible by optimising vehicles powered by internal combustion engines; and a hybrid vehicle, based on a Vauxhall Corsa, that serves as a test lab for various hybrid technologies.

The optimisation measures used in the CO2ncept-10% are already on the market or close to series production, and do not alter the basic configuration of the vehicle which uses electrical components instead of devices previously actuated hydraulically.

The hybrid vehicle can be used to compare a wide range of electric mobility options. Its driving modes range from conventional internal combustion engine operation, to parallel and serial hybrid operating modes using range extenders, as well as all-electric driving modes.

Together, the three vehicles represent Schaeffler’s future strategy and product portfolio for the automotive industry, ranging from efficient systems based on conventional engines, through to hybrid and all-electric systems.

“These three cars are full of ideas and function as platforms for the testing of various components and systems under realistic conditions,” says Gutzmer.