Linear actuators are ‘up to four times faster’

![]() Festo has unveiled a "new class" of electric actuators, based on high-performance linear motors, which it claims can accelerate up to four times faster than other electric and pneumatic axes, as well as being up to three times speedier than electrical axes with spindle or belt drives. The axes, unveiled at the Hannover Fair, can accelerate at up to 140m/s2 and operate to accuracies of 10µm.

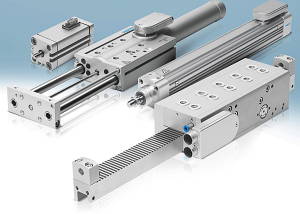

Festo has unveiled a "new class" of electric actuators, based on high-performance linear motors, which it claims can accelerate up to four times faster than other electric and pneumatic axes, as well as being up to three times speedier than electrical axes with spindle or belt drives. The axes, unveiled at the Hannover Fair, can accelerate at up to 140m/s2 and operate to accuracies of 10µm.

There are three types of ready-to-use actuator. The first (called DNCE-LAS) is a maintenance-free linear drive, which allows short-stroke positioning operations to be performed in less than 20ms. It is also available in a guided version (DFME-LAS). Both versions are based on a patented tubular motor technology and have the same interfaces as Festo’s pneumatic axes, allowing them to be used together in multi-axis installations.

The flagship product is a precision linear motor axis (ELGL-LAS) with an air bearing that uses permanent magnets to create an attraction between the carriage and the base. Compressed air fed between the carriage and the base creates an air cushion that lifts the carriage, freeing it from dynamic friction.

These axes, which can operate vertically or horizontally, are driven by synchronous linear motor formed by windings in the carriage that react with magnets in the base. Up to three carriages can run on the same bed and be controlled independently using digital position feedback from built-in transducers. The air bearing makes lubrication and routine maintenance unnecessary, is unaffected by dirt, and is resistant to wear. When the air bearing is switched off, the magnets act as a brake, holding the carriage and any loads without needing extra components.

Initially, there is a choice of six axes – one with a 1m stroke length, and five with 2m strokes and a variety of acceleration, speed and thrust ratings. The most powerful version can deliver acceleration rates up to 46m/s2 and speeds up to 4m/s, and can produce a continuous force of 349N, with a peak rating of 463N.

“Festo’s entry into the linear-motor-based actuator market will hopefully cause people to re-evaluate their opinions about this type of technology,” says Festo’s UK drives manager, Nigel Dawson. “Until now, the use of linear motors for highly dynamic positioning applications, especially those requiring accurate repeatability, has proved something of a black art. We intend to change this, so that system designers eventually come to regard our linear motors as just another actuation technology choice.

“To bring this about,” he adds, “we effectively had to re-invent the linear motor – to come up with a tubular design that can be integrated in actuators with the same form factors as our pneumatic products.”